Email:

info@miocuisine.com

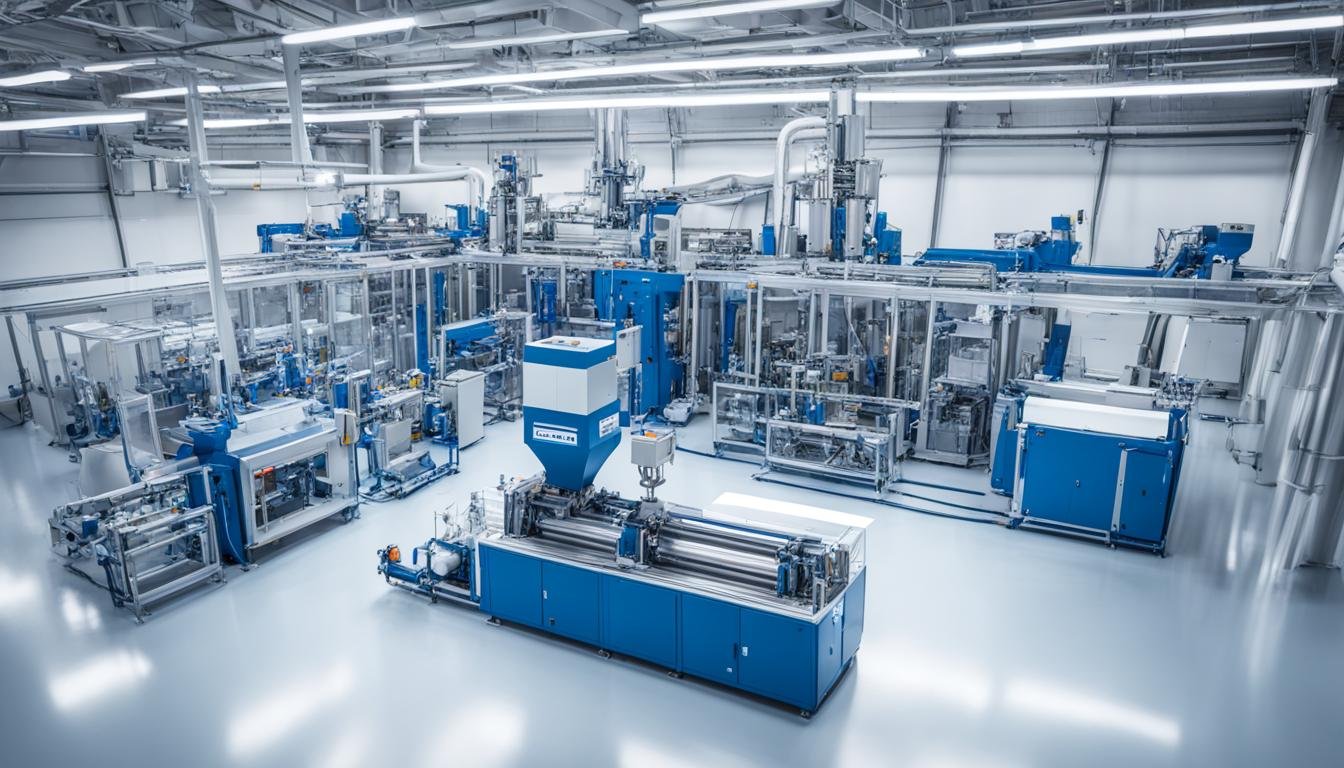

Plastic extruders are key in turning raw materials into various items. Bausano is a top expert in making these machines. They provide plastic extruders that can be customized to fit different business needs. Bausano is focused on quality and coming up with new ways to deal with plastic waste, make recycling equipment, and create sustainable solutions.

They offer machines for labs and big industries, including both single and twin-screw types. These can handle many plastic types, from PVC to HDPE. They can make things like pipes, windows, and medical tubes. Bausano’s extruders can also work with food, like making pet food, showing how adaptable they are.

Bausano uses the latest in recycling tech and adds new features to make recycling plastics easier. They’re known for their high-quality plastic machines. This has made them a go-to for businesses looking to improve how they work and care for the environment.

Plastic extruders are key in making plastic products. They change solid plastic into a hot liquid form. These machines are very important for creating items like containers, bottles, and packaging materials. They work with other machines like injection molding and calenders in making plastics.

Today, plastic extruders are more efficient and cost less due to advanced technology. This lets them work with many types of plastic materials. Manufacturers now meet the high demand for plastic goods because of these modern features.

There are different types of plastic extruders. The most used are single-screw extruders. They are great for processing old plastic into new items. This helps in keeping our planet clean.

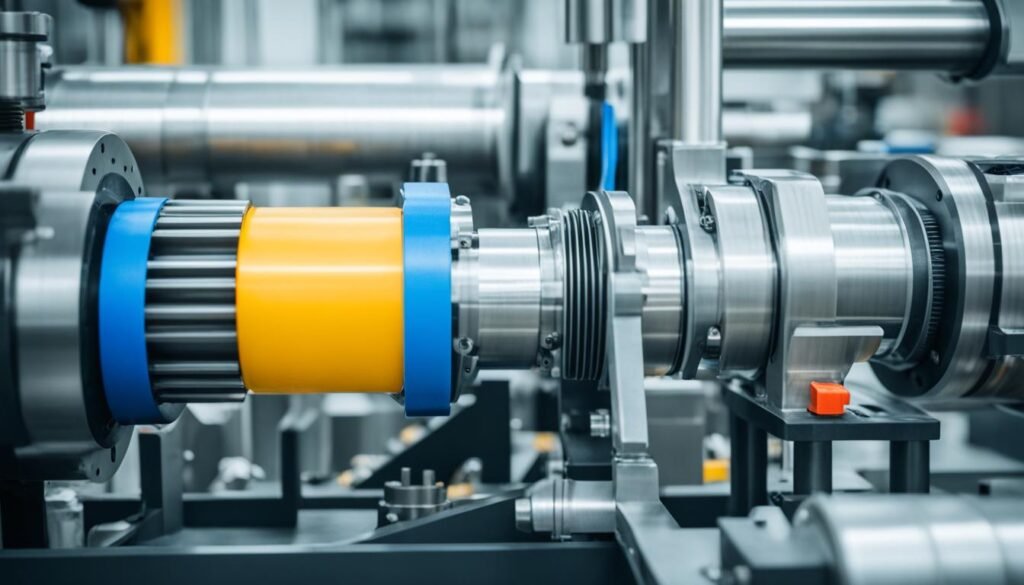

The structure of a plastic extruder typically comprises an extrusion system, a transmission system, and a heating system, each playing a critical role in the waste plastic processing operation.

The extrusion system is made up of a screw, barrel, and hopper. They affect how much the extruder can make. These are created using very strong materials.

The motor, reducer, and screws make up the transmission system, which controls the speed of the screw. This affects how much plastic is produced. Heating is also important. It melts the plastic so it can be made into new items.

Plastic extruders have several good points:

Because of these advantages, plastic extruders are used in many industries. They are perfect for making things like pipes, films, and belts. For instance, the PM-LJ180 model has a powerful motor and can make a variety of products.

| Characteristic | Single-Screw Extruders | Twin-Screw Extruders |

|---|---|---|

| Screw Design | Simple, cost-effective | Complex, more expensive |

| Mixing Capability | Limited | Excellent |

| Material Flexibility | Suitable for most materials | Handles a wider range of materials |

| Output Capacity | Moderate | High |

In conclusion, plastic extruders are vital in the plastic industry. They help make many products we use daily. They also support turning old plastic into new items. With their many uses and efficiency, plastic extruders are very important.

Plastic extruders are key in making many plastic items. They create things like pipes, ideas, and more. These machines can handle different kinds of plastics. For example, they can work with Polyethylene (PE) and Polyvinyl Chloride (PVC).

Plastic extruders use many pieces to work well. These parts help make sure products are top quality.

The hopper is where plastic bits start their journey. It’s like a big bucket that keeps the materials moving. This is important to avoid any stops or clumps that could slow things down.

The barrel is the heart of the extruder. It’s a long, metal part where the plastic gets hot and turns soft. This happens before it’s shaped into the final product. The barrel is strong, made to handle high heat and pressure.

The screw inside the barrel does a lot of work. It helps melt and mix the plastic. This part is shaped like a spiral to push the plastic along as it heats up. The style and size of the screw can change based on what you’re making.

The die shapes the plastic as it comes out. It’s a special tool with different holes or shapes. These shapes make everything from simple pipes to complex parts for cars. The die can be switched to make different products.

| Component | Function |

|---|---|

| Hopper | Holds and feeds plastic raw materials into the extruder barrel |

| Barrel | Houses the screw and melts, mixes, and conveys the plastic material |

| Screw | Melts, mixes, and conveys the plastic material through the barrel |

| Die | Shapes the molten plastic into the desired form as it exits the extruder |

To sum up, plastic extruders use the hopper, barrel, screw, and die to work. These parts are vital for turning plastic pieces into many things. Each part has a special job to do for the whole system to work right and make top-quality products.

In the world of plastic processing machinery, extruders come in various configurations. They serve different applications and materials, enabling efficient production. These machines help create a wide range of products while encouraging sustainable recycling. Now, let’s dive into the main types of plastic extruders and what makes them unique.

Single screw extruders are very common because they work quickly and efficiently. They have only one screw that moves within a barrel. It melts and mixes plastic materials, then pushes them through a die to form the shape needed. These extruders are great at handling many different plastics. This makes them useful in various industries.

Twin screw extruders have two screws that turn together in the barrel. They’re perfect for more complicated tasks like blending and mixing. Thanks to their design, they mix additives and fillers well. Twin screw extruders can also work with tough materials. This makes them crucial for recycling polymer and waste.

Co-extruders make products with multiple plastic layers. They use two or more extruders that combine different materials into one die. This allows for making products with several layers. They are often seen in packaging to create barrier films. They’re also used to make pipes and profiles for specific needs.

Hot melt extruders melt and apply adhesives to products. They work at lower temperatures than regular extruders. These machines are for processing materials like hot melt glues. They are used in packaging, bookbinding, and textile industries. Here, quick and strong adhesive bonds are very important.

| Extruder Type | Key Features | Applications |

|---|---|---|

| Single Screw Extruders | High processing efficiency, versatile | Wide range of industries and products |

| Twin Screw Extruders | Better mixing and dispersion, handles challenging materials | Compounding, blending, advanced recycling |

| Co-Extruders | Creates multi-layered products | Packaging, pipes, profiles with specific properties |

| Hot Melt Extruders | Processes thermoplastic adhesives at lower temperatures | Packaging, bookbinding, textile manufacturing |

Understanding the different kinds of plastic extruders helps manufacturers. They choose the best machinery for their needs. This ensures their production is efficient, creates high-quality products, and is good for the environment.

Plastic extruders are key in making new items and recycling old ones. These machines are important in the manufacturing world. They manage plastic waste well and help with recycling.

These machines turn used plastics into new, useful things. They work with many plastic types like PET, HDPE, and PVC. This stops a lot of trash from going to landfills, helping our environment stay clean.

This means extruders can keep making things without a lot of leftover material. They can make items with different looks and structures all at once. Plastic pipe lines, for example, can make lots of products fast. This saves both time and materials.

Using plastic extruders saves money too. They use materials efficiently and can recycle old ones. They make plastic items that are the same size all over, great for things like plastic sheets.

| Plastic Extruder Benefit | Description |

|---|---|

| Versatility | Capable of producing a wide range of products, from simple pipes to complex profiles and shapes |

| High Quality Output | Produces products with consistent dimensions and specifications |

| Efficiency | Quickly produces large volumes of products at a relatively low cost |

| Plastic Waste Management | Transforms post-consumer plastics into valuable materials, reducing waste sent to landfills |

| Sustainable Recycling Solutions | Promotes sustainability by efficiently recycling plastic waste into new products |

Advanced equipment adds even more value to plastic extruders. For instance, dual shaft plastic shredders can handle more, as they shred materials, and rigid washing lines clean hard plastics well. This makes recycling more efficient and sustainable.

Overall, plastic extruders bring many benefits to making and recycling items. They help use materials wisely. And when paired with the latest equipment, they further boost production and sustainability. This brightens the future for both makers and the planet.

Plastic extruders are key in making many plastic products across different fields. They can work with lots of plastic types, from high-density polyethylene to PVC. Thanks to over 100 years of experience, manufacturers are skilled at meeting various needs with quality products.

They’re vital for making plastic pipes and tubes for things like construction and irrigation. The process creates strong, lasting pipes and tubes that fit standards well.

They also make plastic profiles and shapes for construction projects. Products like window frames and trim pieces are essential for renovation work. This offers a budget-friendly option with low upkeep.

Plastic extruders create thin films and sheets used for food packaging and covering crops. The films and sheets come out evenly thin, clear, and strong, perfect for their tasks.

They’re important in making plastic bottles and containers for drinks, beauty products, and more. The process ensures these containers are strong and even in thickness. This supports various industries like window making and adhesive production.

Plastic extruders also make the granules and pellets needed for other plastic products. By blending plastic resins and colors, a consistent and quality raw material is achieved. This is then used in making other plastic items.

Recycling plastic is a major task for plastic extruders. They turn used plastic into new items, which cuts down on waste and saves energy. This is key in addressing our planet’s environmental challenges.

They also produce plastic coatings, great for adding a layer of protection. These coatings work well in vehicles, planes, and everyday items, making them last longer. The process makes sure the coating sticks well and looks good.

| Application | Products | Industries Served |

|---|---|---|

| Manufacturing Plastic Pipes and Tubing | PVC, HDPE, and PPR pipes | Construction, Agricultural Irrigation, Plumbing and Drainage |

| Extruding Plastic Profiles and Shapes | Window frames, Door frames, Trim pieces | Construction, Renovation |

| Producing Plastic Film and Sheets | Packaging films, Agricultural films | Packaging, Agriculture |

| Manufacturing Plastic Bottles and Containers | Beverage bottles, Personal care containers, Household goods containers | Food and Beverage, Personal Care, Consumer Goods |

| Creating Plastic Granules and Pellets | Raw materials for other plastic products | Plastic Manufacturing |

| Recycling Plastic Waste | Recycled plastic products | Waste Management, Sustainability |

| Creating Plastic Coatings | Protective and decorative coatings | Automotive, Aerospace, Consumer Goods |

Plastic extruders are critical in today’s plastic-making world. They’re essential for making a variety of products and are pushing innovation forward. As the need for plastic items grows, their role in manufacturing becomes more important than ever.

Plastic recycling machines are changing the game in waste management. They can handle big amounts of plastic waste effectively. This equipment also creates high-quality recycled materials. These materials can go back into making new products. Their advanced technology makes them efficient, easy to use, reliable, durable, and versatile.

Modern plastic recycling machines are extremely efficient. They can quickly process a lot of plastic waste. This helps save energy and produce more recycled products. These machines can recycle over 700,000 tons of plastic each year. They are a big help in the fight against plastic waste. Their high efficiency also makes recycling cost-effective. This is good for the environment and the economy.

Plastic recycling machines are made to be user-friendly. They have easy-to-use controls. This makes recycling simple for people with different levels of experience. They help prevent mistakes and make production more efficient. This improves how we manage plastic waste.

When you buy a plastic recycling machine, you’re making a long-term investment. It’s crucial to choose a machine that is reliable and durable. Companies like EREMA build their machines to last. They use high-quality materials. This means the machines work well for a long time with less maintenance. With over 7,000 EREMA systems around the world, their quality is clear.

Plastic recycling machines can work with many types of plastic. Whether it’s from consumers, production, or bottles, they can handle it. These machines can be set up to make different products like pipes or films. This lets recycling facilities meet the changing needs of their markets. EREMA and similar companies offer custom solutions for any application. They make sure their customers get the technology they need.

| Company | Recycling Capacity | Installed Plants | Completed Projects | Employees | Machine Patents |

|---|---|---|---|---|---|

| Amstar Machinery Co., Ltd | 700,000+ tons annually | 80+ | 89+ | 300+ | 113+ |

| EREMA | 18.5 million tonnes annually | 7,000+ systems worldwide | N/A | N/A | N/A |

The table above shows the amazing work of top plastic recycling machine makers. These companies have huge recycling capabilities and a lot of plants. They are leading the way in finding sustainable solutions for plastic waste. Their work is crucial for a cleaner, greener planet.

At Antecs, we know not every plastic processing need is the same. Our customized plastic extruders are made just for you. They help boost production and meet the specific needs of different industries. We work closely with you to create the perfect recycling equipment that makes your operations more efficient. We help you provide sustainable recycling solutions.

Antecs is all about polymer recycling and managing plastic waste. We’ve made hundreds of thousands of products from recycled plastics, turning tons of waste back into something useful. Our extruders can handle many types of plastic, making items like pipes, films, and even automotive parts.

We don’t just sell machines. Antecs offers full technical and customer support. Our help includes:

Choosing Antecs means your plastic processing operations run smoothly. We focus on excellence and keeping you satisfied. Our machines are safe and meet all standards, making your investment secure for your recycling projects.

“Antecs has changed everything about our plastic recycling. Their special extruders let us turn many kinds of waste plastic into high-quality goods. Their team has given us great advice and support to improve our work and reach our eco-goals.”

– John Smith, CEO of GreenTech Recycling

Be part of the hundreds of businesses working with Antecs to recycle more efficiently. Let our customized plastic extruders improve how you manage plastic waste. Contact us to talk about your needs and see how we can help meet your eco-friendly goals.

In recent years, the plastic extrusion industry has seen big improvements. These are because of the push for better and greener ways to make plastic items. The changes make plastic goods better and help the planet too.

The use of Industry 4.0 in making plastic items is a big step forward. It means using smart tools and computers to control how things are made. This helps make better things and makes less waste.

More and more, people want products that don’t harm the earth. To answer this, makers are using materials that can break down easily. These come from things like corn and sugarcane. This change is making plastic production less harmful to our planet.

Using less energy is a big goal for those making plastic items. Makers are finding new ways to heat and move plastic without using too much energy. These new methods not only save money but also help the environment.

Making plastic items well every time is very important. New control systems help with this. They make sure everything is run just right. So, the plastic items are always the best they can be.

| Advancement | Benefits |

|---|---|

| Industry 4.0 Integration | Improved product quality, reduced waste, enhanced efficiency, and cost savings |

| Biodegradable Materials | Reduced environmental impact, alignment with consumer demand for sustainable products |

| Energy Efficiency Measures | Cost savings, reduced carbon footprint, extended equipment lifespan |

| Precision Control Systems | Consistent product quality, quick changeovers, increased productivity, real-time quality monitoring |

All these updates in plastic making are changing the game. Makers can now make high-quality, earth-friendly products for less. By using these new ways, companies can be leaders in their field.

Sustainability is now more crucial than ever, affecting us all, especially in the plastic industry. With global worries about plastic waste and the environment, companies must cut their carbon footprint. This means reducing waste and energy use while pushing for sustainable plastic processing.

Essentra Components is a champion in green recycling. They make LPDE items like tapered caps, corner protectors, and more from 98% recycled plastic and 2% colorants. This clever method doesn’t just save resources, it also cuts the need for new plastics.

Recycling plastic saves more than just waste. It uses up to 75% less energy than making new plastic, which helps the planet by lowering greenhouse gases. This paves the way for a greener, more sustainable world.

More plastic recycling means fewer landfills and less harmful gas like methane in our air. By recycling old plastic into new, products in a closed loop, we cut down on the oil and gas needed for new materials.

| Recycling Benefit | Impact |

|---|---|

| Energy Savings | 75% less energy required to produce a plastic bottle from recycled polymers |

| Landfill Reduction | Decreasing waste in the environment and minimizing the release of landfill gases |

| Circular Economy | Reducing demand for raw materials used in the production of virgin plastics |

| Carbon Footprint | Saving over 1kg of carbon dioxide per month per individual compared to standard waste production |

By embracing recycling, companies can truly change the game for our planet. Using more recycled material in their products, firms like Essentra are leading the way. They show that using innovation with quality is achievable.

The plastic waste problem remains tough, but the solution is clear: focus on sustainability. Companies must put their efforts into green practices and recycling tech. This way, they help the Earth and secure a better tomorrow for all.

Choosing a plastic extruder manufacturer is crucial for your business. The right one can boost your plastic processing. It’s important to consider several aspects before making a decision.

Pay attention to a manufacturer’s experience and expertise. Go for a company with a good track record in making high-quality machinery. RETECH, for instance, has a team with more than 15 years of experience in the plastic recycling industry.

The manufacturer’s knowledge about different materials and applications is also vital. They should be able to produce machines for a wide array of needs. Look for a team that knows about different types of plastic recycling equipment.

The quality of your plastic extruder affects your products and operation. It’s crucial to check the manufacturer’s quality control. Established brands are usually more reliable because they maintain strict quality standards.

Ensure the manufacturer uses top-notch components. For example, they should use components from brands like Siemens, Omron, and ABB. The quality of the parts and construction plays a big role in the extruder’s performance and life span.

Buying a plastic extruder means a long-term partnership. The manufacturer’s support can significantly impact your experience. Look for one that offers installation, training, and maintenance services.

Additionally, check how they handle repairs and spare parts. A good manufacturer keeps spare parts in stock and offers maintenance guidelines. This helps you keep your extruder running smoothly for a long time.

| Factor | Importance |

|---|---|

| Experience and Expertise | Ensures the manufacturer has the knowledge and skills to deliver reliable and efficient solutions |

| Quality Assurance | Directly impacts the quality of end products and the efficiency of operations |

| After-sales Service and Support | Minimizes downtime and ensures smooth operation of plastic processing machinery |

While selecting a plastic extruder manufacturer, remember these points. Doing thorough research can help you choose wisely. This choice is key to your business’s future success in plastic processing.

Plastic extruders are key in many fields, helping make a wide mix of products. They are vital in making plastic pipes, profiles, and films. This process is important for recycling and managing plastic waste.

In construction, these machines create pipes for plumbing and drainage. They also make plastic parts like window and door frames. These find use in building and upgrading structures.

They are additionally used to make plastic films. These films do packaging, cover fields, and protect items. Such uses help cut down on waste.

Extruders play a big part in the wire and cable industry. They make protective layers for cables. Also, they craft materials like WPC for outdoor use.

The global plastic recycling machine market generated a revenue of US$ 3,033.42 million in 2022, with a projected valuation of US$ 5,035.43 million by 2031, indicating a compound annual growth rate (CAGR) of 6.13% for the period.

In the auto field, extruders help make parts like bumpers and dashboards. These products are durable, light, and improve the car’s performance.

The medical world uses special extruders for tubing. These tubes are crucial for things like IVs and are made to high medical standards.

| Market Segment | Share in 2022 | Projected Value by 2031 | CAGR (2023-2031) |

|---|---|---|---|

| Crushing Machines | 18.83% | – | 7.74% |

| Post-Consumer Recycling | – | – | 6.64% |

| OEM | 83.16% | US$ 4,048.09 million | – |

| Aftermarket | – | – | 7.93% |

The need for better plastic recycling is growing. This drives the market for plastic recycling tools. The market is set to be worth US$ 5,035.43 million by 2031, from US$ 3,033.42 million in 2022.

Companies like Amstar Machinery and Munchy are at the forefront. They keep creating new tech for polymer recycling. This meets the rising need for sustainable solutions in different sectors.

Plastic recycling machines and plastic extruders are key to making our world cleaner and greener. They reduce the amount of plastic waste we have, making things better for the environment. These machines also help save energy and materials, cutting down on the cost to make new things.

The plastic recycling industry is also good for creating jobs. It helps the economy to grow. Plus, it keeps plastic out of our oceans and landfills.

Plastic processing machinery is important for many areas. It’s used at home, at work, and in big industries. These machines can handle all kinds of plastic waste. They work with items like bottles, containers, packaging, and more.

Sustainable recycling solutions and recycling equipment are key for good plastic waste management. They help us deal with plastic waste in a smart and eco-friendly way.

For polymer recycling to get even better, we need everyone to work together. Governments, businesses, and regular people must team up. This cooperation will help us use better machines and methods for recycling. The future of plastic recycling is all about being more efficient and friendly to our planet.

Investing in high-tech plastic recycling machines is a step towards a cleaner earth. These machines are essential for meeting the demands of a sustainable future. They also help us reduce the harm plastic waste does to our environment.