Email:

info@miocuisine.com

Injection molding, a process for making parts to prints, can best be described as an endeavor to produce a well-conformed plastic system. The operation involves feeding a measured amount of polymer in the form of granules into a hopper, feeding this material into a heated chamber and melting it, then forcing this material into a mold cavity where it cools and hardens to the configuration of the cavity. Optimization can be defined as an act, process, or methodology of making something (such as a design, system, or decision) as fully perfect, functional, or effective as possible; specifically, the mathematical procedures (such as finding the maximum or minimum of a function) involved in this. This can be directly related to the injection molding process, which involves improving a system or design. Therefore, injection molding process optimization refers to the method in which the process is improved, whether it is in the quality of the system or design, reducing cycle times, or improving molded part quality. This involves identifying the problem and then finding the most effective method to solve the issue.

The term ‘optimization’ has been used since the late 19th century to describe making the best or the most effective use of something. In a general sense, optimization aims to make things better than they currently are, by doing the same work using fewer resources or doing better work with the same amount of resources. For the molding process, the same amount of resources would be defined as the same cycle time and press capacity. Better work would be defined as improving part quality or improving efficiency. Improvement of part quality can be seen as reducing or eliminating a defect so that a molded part is acceptable, no matter what the application. A chip on a cell phone case that is cosmetically unacceptable can be considered a reject. Often these rejects can be the same cost as the acceptable part, so it is very important to optimize and improve part quality to ensure a high yield of good parts. High efficiency can be looked at from a number of perspectives. For the mold maker or the molder, it can mean being able to complete a job in less time, or it can mean completing a job in the same amount of time but freeing up press capacity for other jobs. Typically, a mold maker will be considered more efficient if they can complete a job in less time, and typically a molder will be more efficient if they can complete a job using fewer hours on the press. For the part designer, efficiency can be improving the quality of a part with the same cycle time. This would be a trade-off in improving part quality using the same resources. In a simple sense, optimization in the molding process aims to produce the highest quality and most efficient part using the least resources.

Improving production efficiency and product quality is a universal concern in today’s competitive manufacturing environment. In the 21st century, manufacturing is changing from a low value, high labor cost model to a high value, low labor cost model in order to compete globally. This is especially significant to the western world, where traditional manufacturing is being moved to lower cost countries, with the higher value work staying in the west. To remain competitive, western manufacturing companies must ensure their production processes, including quality control, can identify and eliminate defects in the cheapest possible manner. The aim of many manufacturing companies is to have an efficient, automated production process with minimal downtime and near perfect quality control. These companies are unlikely to have reached this goal, and many still using traditional “low-tech” methods, thus providing an opportunity and incentive to improve with the use of systematic process such as process optimization. Simulation-based process optimization can be a valuable tool for current production process analysis, identifying problems and areas for improvement. However, it is often most valuable for the analysis of new processes or process redesign, providing the ability to ensure a new system is capable of meeting production and quality targets prior to implementation.

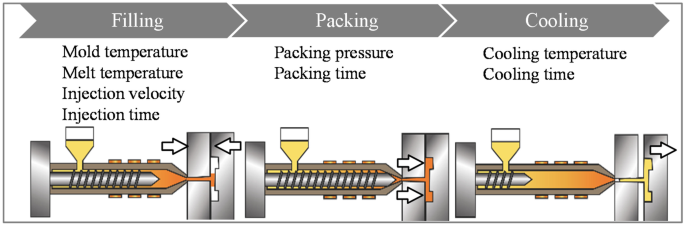

Molders and manufacturing engineers cooperate with part designers to make sure that the plastic molder is correctly designed to utilize the specified material and to make the parts to exact specifications. When designing the mold, engineers need to maintain an even wall thickness throughout the part and mold. A uniform wall thickness will help minimize variations in shrink and warpage. Gates and runners need to be designed as large as possible, to minimize their effect on part packing and consistency. All sharp corners and edges on the part design need to be molded with proper radii to reduce stress and part distortion. Texture or a polished finish on the mold will greatly affect the surface appearance and resin flow of the finished part. Machine setting parameters set in the first stage of the process will vary depending on the type of material, part design and size, mold requirements and machine capabilities. Typically, filling is conducted at a high speed with the capability to switch over to a controlled or semi-controlled packing stage. Sufficient cooling time, and a fast mold close-up time, are other key factors in making good quality parts while reducing cycle time.

Material selection is important for any manufacturing process, and the same is the case for injection molding. A working knowledge of the material properties is critical, and the relative properties of different materials affect how they will perform in a given application. A material that might be perfect for a certain application in theory might not translate well into real life. Whereas a material with slightly different properties might perform better. An example of this would be a material with higher impact strength at a low temperature. If the part is going to be used in a cold climate, this would be a superior choice to a material that has higher impact strength at a high temperature. The material with low temperature impact can still perform well at a high temperature, but the same can’t be said for the high temperature material performing well at a low temperature. The superior material might be more expensive, and this is an important consideration, but the relative cost of the material compared to the cost of a product failure is very important. With the high cost of tooling and production equipment, a material failure can be a very costly problem to fix. If the part requirement is for a long-lasting high volume product, taking the time to really understand the material properties and selecting the best material for the job is time well spent.

Mold design and construction is a critical step in the manufacturing process. A mold with the right specifications will allow for higher quality parts, increased production efficiency, and longer mold life. Some considerations when designing and constructing a mold include draft angles, channels, and undercuts. The mold should be designed with consideration of the molding process to be used and the desired parts. If it is to be a high production mold with a low melting material, the mold will need to be constructed out of high-grade steels in order to withstand the process. This is especially important in the case of metal injection molding. A high production mold will also require the use of multi-cavity tooling. The general rule is the longer the mold life required, the higher the construction cost will be. A properly designed and constructed mold can easily justify its costs through part quality, consistency, and long-run production.

One of the interesting findings of that research was to do with the effect of mold velocity on the swirl of the molten polymer. Swirl is caused by the difference between the velocity of the mold and the velocity of the polymer at the mold wall. When the swirl is formed, it remains until the part is ejected from the mold and can result in variations in mechanical and thermal properties. Factors such as the performance capabilities of the machine, the size of the mold and its complexity, as well as the material being used, all affect the range of machine settings. Now more than ever, it is vital to optimize process and production efficiency while minimizing costs to remain competitive in this tough market.

Injection molding process efficiency is greatly affected by the setting of the injection machinery. Previous research has provided evidence to support machine settings’ effect on part quality and productivity. Many of the issues addressed in this research involve the effect of machine settings on part quality. Machine settings have a big influence on the rate at which molded material enters the part. This, in turn, can affect weld lines and part strength. Susceptibility to part defects is increased in components with long flow lengths and/or wall thickness. This occurs particularly when the mold is situated in the machine under certain settings and is removed and then reinstalled on the same or a different machine.

Step 5: Repeat steps 1-4. During the next four steps various inputs can be changed and the effects can be easily compared. The final DOE should involve minimum and maximum acceptable inputs.

Step 4: Cool the part. Use a short cooling time to allow easy part removal. Monitor the part quality during cooling. The mold should stay closed until the part is sufficiently cooled.

Step 3: Pack the mold by holding a constant pressure. This is where the part quality is determined. Pack the mold by holding a constant pressure. Times can range from 10 seconds to 2 minutes.

Step 2: Fill mold to 95% ± 5% full to the part at the fastest fill rate possible without creating a flash. Monitor the mold pressure and transfer to second stage at 95% ± 5% full to the part. Fill the mold to 95% ± 5% full to the part at the fastest fill rate possible without creating a flash.

Step 1: Determine melt temperature by using a first stage temperature set up that will provide 95% ± 5% full to the part with 1-2 second hold time. Fill the mold at the fastest rate possible without creating short shots.

Injection molding process can be optimized using several techniques and approaches. These may include trial and error approach, design of experiments, and systematic processing. Techniques and approaches used to optimize injection molding processes are similar to scientific methods as it is logical, systematic, and repeatable. In general, the scientific molding processing is a technique wherein the process is developed and optimized to meet the part quality and productivity requirements. The scientific molding approach is divided into several steps as follows:

The proceedings that mold from the scientific molding area are offered to supply a roadmap for activity method improvement. The highest purpose of the work is to develop an optimized method in a state where very fine management of method variables is achieved. It becomes possible to shoot into an especially little cavity sometimes accustomed manufacture a medical element. If an oven or autoclave is employed to precondition plastic before molding or if plastic is leave the machine(s) at variable wet levels, this methodology is also accustomed verify half quality vis a vie method capability. Scientific molding is also the ideal method for prime production programs or very important half demands. It will even be used as a comprehensive method within a bigger manufacturing organization or set up if the simulation model concerned is dynamically valid to all method conditions that the half will encounter. Simulation models sometimes simulate plastic flow of a 2nd or 3D solid model and embrace processing effects like material change of state, compression, and heat transfer. Simulation modeling is cost-effective for the development of a latest method or determining if an existing method is capable of manufacturing high-quality parts.

Advancement in technology in the late 20th century has led to the development of automatic closed-loop process control systems. Such control systems provide a means to screen and possibly adjust injection moulding process parameters indicated by a comparison of real-time and historical data. The development of an automatic closed-loop process control system is a very complex and therefore costly task. Typically, these control systems have been reserved for only the highest of production environments where the cost of failure is highest. A substantial amount of research has been performed to identify key moulding process parameters and the extent to which they may be accurately controlled. 21 process parameters, including cavity pressure, that affect the quality of an injection moulded part were identified through industry and academic research. The same research concluded that only 2 of these parameters; cavity pressure and resin temperature were controllable to a reasonable extent. It is now known that cavity pressure may be controlled with excellent repeatability and used as a quality feedback signal in process monitoring systems measuring part quality. This research ultimately led to the development of a scientific moulding approach and the implementation of process monitoring and control systems on a large scale in order to maximize control over the injection moulding process. Initially, process monitoring and control systems were designed as an off-line quality control means through the recording of process data and/or part inspection results. The intent was to detect and possibly correct any unfavorable process parameter variations, position changes, or tool and die wear, borne from normal toil or environmental influences. An example would be the setting of an alarm to indicate an undesirable deviation from a set process parameter. In this case, the alarm acts as a warning of increased scrap and/or downtime to follow if corrective action is not taken.

MFA works by using a small mesh boundary around a product or tool in a virtual molding environment. Polymer flow through the mold is simulated by calculating pressure, temperature, and cooling rate at any point in the mesh throughout the mold fill process – Gate start to Gate Freeze. The best results occur with a highly detailed model of the tool and all inserts and sliders. This way, joined with the right molding material, an almost identical environment is created, comparable to what will be seen in the real molding application. The results can then be used to identify aesthetic and structural issues with a part as well as a wide range of tooling issues. It allows user interaction, which means changes can be made and quickly validated to see what effect they will have. A back-to-back comparison can also show if the problem has been solved and what the best solution was. This can vastly reduce the time required to rectify an issue during the real molding process.

Moldflow analysis or MFA is a technique used in plastic injection molding which allows the identification of possible problems that could occur during the tooling process. MFA can be a very useful tool in the beginning and maintaining quality levels for both the injection molder and product design division of a company. MFA provides valuable information in pursuit of the root cause of a manufacturing issue and can offer suggestions that could fix the problem and provide more efficient tool design, and validation of existing tooling for possible improvements.

The ability to optimize a process is often significantly influenced by part design. In fact, the design of the part can dictate what process is to be used and the settings that are required for that process to produce acceptable results. Design for manufacturability is an approach to part design that focuses on the ability of the process to produce the part at the required tolerances and rate. This approach considers the process and material as an integral part of the design process and the results are designs that are easier to produce with less variability in the end product. Studies have shown that a high percentage of the cost of an injection molded part is locked in by decisions made during the first few stages of the product design process. When changes are made to the part design late in the development cycle, the effects on the project’s timeline and cost can be severe. Therefore, the greatest potential for cost savings through process optimization can be achieved through part design changes.

Increased production efficiency through optimization is the top benefit, as it has the largest impact on the total manufacturing cost. Many engineers have the goal of making the process as efficient as possible, achieving the maximum output from the smallest input. This can take the form of various setups; cycle time reduction is a good example of a post-process optimization technique. For injection molding, however, the key to efficiency is maximizing the number of good parts produced and minimizing the downtime required to do this. Running a mold until the quality of the parts produced is so poor that they are rejected can be very costly and does not add any value to the part. Making repairs to a poor quality part can be even more costly. Thus, the optimum goal is to run the mold at the minimum cycle time, producing good parts, and with no need for part rework or mold repairs. Step one is to simply identify what the appropriate cycle time and machine set-up are to produce good parts. This is where implementation of engineering analysis can first be seen in the mold tryout phase, but even more so once a validated processing method has been established. By using Moldflow Plastics Insight (MPI) process simulation results for a specific mold and material, they can be compared with the actual part/mold data to identify the cause of any discrepancies in part quality and to determine the appropriate corrective action. This is useful information, but likely even more useful is the development of an in-process quality control method, such as the Design Of Experiments (DOE) method developed by the industrial engineering community. Such a method provides a means to determine the impact of various process parameters on the part output and to optimize these parameters to maximize the throughput of good parts. Simulation and development of such control methods require varying degrees of increased technical sophistication, but the potential improvement to production efficiency should not be underestimated.

With the use of a formal tone, explain the benefits of optimization across the three categories in section 4. Think about how optimization will improve efficiency, quality, and cost/waste, then compile the responses together, still using a formal tone. These are the main selling points to convince a company to consider using the optimization strategies in their molding process.

The improvement in material technology and modern manufacturing equipment has been strategically designed to improve efficiency and reliability of the injection molding process. One material technology that has been substantial in improving process efficiency is the development of thermal control systems for injection molds. This technology has been devised to heat the molds quickly and efficiently, while preventing the mold from overheating by regulating the heat delivered to the mold using heat transfer devices such as heat pipes. Although this can be an expensive method for high volume or long-term production, the results are more than satisfying. The increased efficiency and productivity given by reduced cycle time and improved part quality is often more cost-effective in the long run. In terms of reliability and efficiency, the newly developed mold heating and control system has the potential to significantly reduce quality variation in the injection molding process. In the same way that temperature control is essential to prevent voids and weld lines, it is also critical in preventing variation in shrinkage and warpage in the molded parts. A more recent development in injection mold heating technology is the use of induction heating in the steel mold. While this is a costly method, the process efficiency benefits may make it a viable option for certain applications. Induction heating is able to heat the mold surface to a precise and consistent temperature very rapidly. It also negates the risk of localized overheating and has no impact on the injection molding machine’s cycle time.

Another common quality issue is surface blemishes such as burn or air traps. Going back and attempting to change the existing process, being mild or drastic, to identify the source or resolve these problems can be time-consuming and costly. Simulation software can pinpoint the necessary adjustments and mold modifications that will resolve the problem.

What are the potential problems that process optimization can resolve? Closer tolerances are becoming more common, but parts sinks and warp are still frequent occurrences. Sink occurs when there is an area of thickness in the part. During the cooling stage, this spot will attempt to become solid by taking material from the thicker wall. This may affect the appearance of the part or its ability to fit/function as an assembly. Warp is caused by non-uniform shrinkage during the cooling stage. There are several reasons this can occur. One common scenario is a part being ejected from the mold too hot and then changing shape once at ambient temperature. A warped part can become an aggravating ordeal trying to fit and function in assembly. Both warp and sink can be resolved by making changes to packing and cooling stages of the process.

To a company producing a line of products, production efficiency, quality control, and saving money are crucial. An optimized injection molding process is one way to obtain these goals. To begin, the definition of process optimization should be explained. This is to take an existing mold and process and make the necessary/possible adjustments to improve part quality, increase machine efficiency, and reduce cycle time. Simulation software has become an invaluable tool for identifying and implementing these improvements. Any change to a mold or process can potentially affect another area of the part or process. By using the simulation, the processor can understand how to resolve problems without having to use trial and error, which can be time-consuming and produce useless scrap.

Typically, the elements of successful injection molding are identified when the parts are transferred to other functions for their subsequent value-added steps. When parts are removed from the process too soon, it is usually a result of not understanding the true cost of the part. Eliminating quality defects and improving process capabilities can often be used to directly optimize costs from the current process. This can be done using advanced process monitoring and a scientific molding approach. Development of a decoupled molding strategy with standardized machine set-ups and built-in process parameters for best results can also be used. Through implementation of these strategies, a molder can achieve consistency from machine to machine and from one process to another. This is a key to success in transferring process optimization achievements to a customer’s application and simultaneous achievement of cost reduction and waste minimization. The clinical aspect of scientific molding with emphasis on establishing reproducible processes sets the stage for realization of VAVE (value-added and value engineering) stemming from improved process capabilities. Identification of the true cost of the part is the ratio that the best process parameter settings have on cycle time and part quality. It is the last key recommendation and should be done in every case whether it is a case of VAVE or a new tool trying to optimize a new process.