Email:

info@miocuisine.com

In the plastic manufacturing world, plastic extruders play a critical role. They help make a wide variety of products. These machines take raw plastic in the form of small pellets and turn them into shapes we need. They can make items like rods, tubes, and sheets to meet different industry demands.

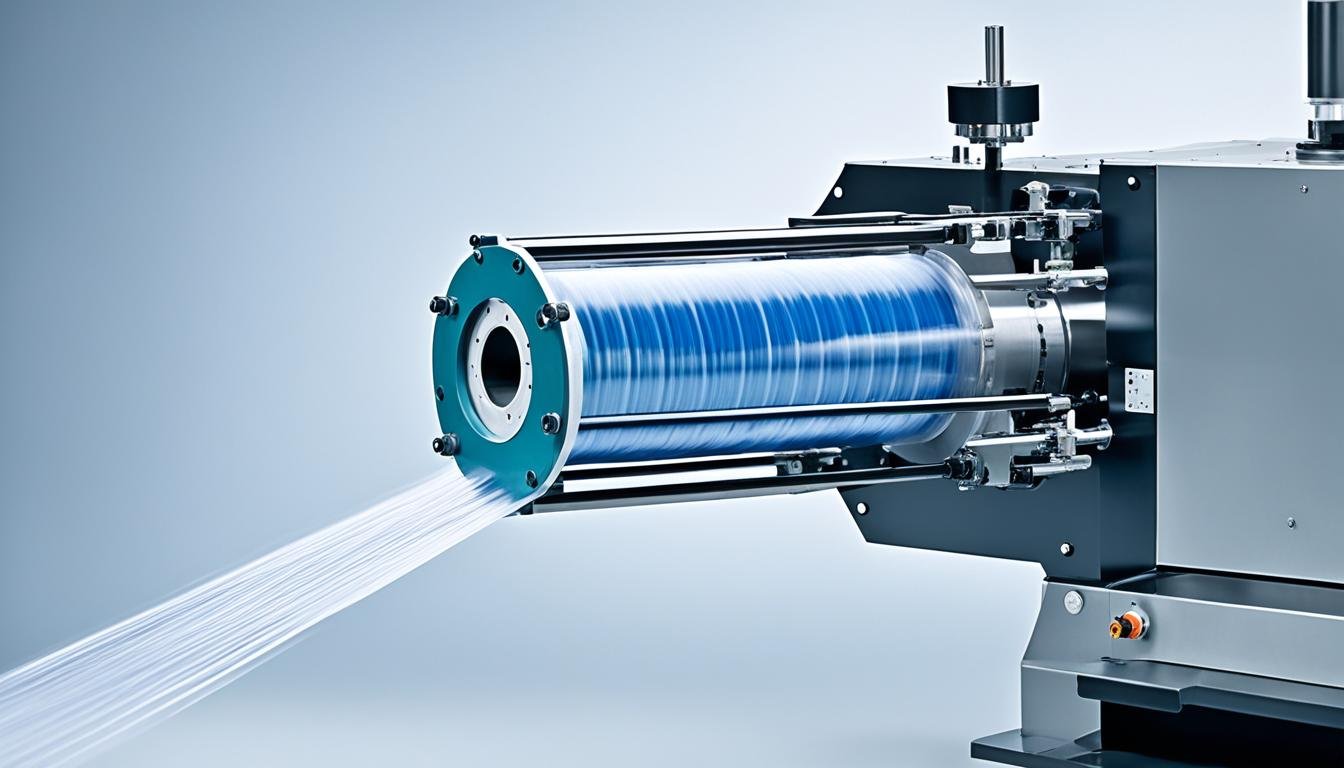

A plastic extruder has three main parts: a screw, a barrel, and a motor to drive the screw. Working together, these parts make production efficient and uniform. Bausano is a top manufacturer of plastic extruders, offering models that meet various needs. They are known for their innovative extrusion die tooling and extruder screw design, which helps in making top-quality thermoplastic molding equipment.

The need for high-quality plastic items is growing across many fields. As a result, plastic extruders are key machines for many manufacturers. They help companies make a lot of products cost-efficiently without compromising quality. They use the latest technology and designs to meet these demands.

Plastic extrusion machines, or extruders, are crucial in making many products. They turn raw plastic into shapes like pipes and sheets. Using heat, pressure, and a die, the extrusion process crafts these items.

Plastic extrusion changes small beads into one-size products. First, the material goes into a hopper. Then, a screw pushes it through a heated barrel.

Inside the barrel, the plastic melts and mixes. Finally, it’s pushed out of a die into its final shape.

A plastic extruder has several main parts critical for smooth operation. They are:

Plastic extrusion uses materials like polyethylene and polypropylene. These are selected for their unique qualities and how the final product will be used.

The process is very adaptable, making many different items. Choosing the right materials and settings is crucial for success.

Plastic extrusion is a versatile manufacturing process that enables the production of a wide range of products, from simple tubing and piping to complex profiles and shapes. The key to successful extrusion lies in the proper selection of raw materials, extruder components, and process parameters.

There are several types of plastic extrusion machinery, each focused on different manufacturing needs and materials. We have single-screw, multiple-screw, and ram extruders. It’s important to know what sets them apart to pick the right one for your work.

Single-screw extruders are very common. They have a screw that turns in a barrel. This action heats up and shapes the plastic. They work well for making a variety of plastic products. They are easy to use, not too expensive, and can handle many kinds of plastic.

Twin-screw extruders have two screws. They mix materials better and work faster than single screw ones. They can do more, like adding different materials together or forming new materials in special ways. However, they are a bit more complex and costly.

| Extruder Type | Key Features | Applications |

|---|---|---|

| Single-Screw | Simple design, affordable, versatile | General-purpose extrusion, wide range of thermoplastics |

| Twin-Screw | Superior mixing, high efficiency, special features | Compounding, reactive extrusion, processing filled materials |

Ram extruders are different. They use a plunger, not a screw, to shape plastic. They are best for some kinds of plastic that give other machines trouble. They are simple but not used as often because they are slower and can’t work with every material.

Choosing the right plastic processing equipment means looking at the material, what you want to make, and how it will be used. Each kind of extruder has its own benefits and uses. Knowing about them helps you make the best choice for your work.

Plastic extrusion machines make it easier for manufacturers to create plastic items quickly and at a low cost. They can handle big orders and work with many types of plastic. This means they are perfect for all kinds of businesses.

These machines can make a lot of products at once without losing quality. This skill helps businesses save money because it’s cheaper to make each item when lots are being made. Also, since these machines can run all day, companies don’t have to worry about running out of products to sell.

Extrusion machines are very flexible and can work with many different plastics. They can use materials like PE, PP, PVC, PS, and ABS. This lets companies make products tailored to many industries, such as health care, cars, buildings, electronics, and food.

Manufacturers can also mix different materials to change how the products look or perform. They can add things to make products last longer, be stronger, or even resist fire. This flexibility means the sky’s the limit for what can be made.

Plastic extruders are great at making plastic items in all sorts of shapes and sizes very accurately. They can produce things that are short or long with precision. This is key to ensuring every item is the same and works well.

| Benefit | Description |

|---|---|

| Cost-effective production | Plastic extrusion has a lower cost compared to other plastic processes and is more efficient, with tooling being cheaper than other manufacturing methods. |

| Aesthetic appeal | Plastic extrusions can be made in a variety of colors and finishes, providing an attractive appearance for the final products. |

| Polymer processing advantages | Plastic extrusion offers benefits such as melting and shaping thermoplastic materials according to the die, and cooling the extrudate to its final form, making it a versatile process for various applications. |

To sum up, plastic extrusion machines offer many benefits, like being able to make a lot of items at once at a good price, working with lots of different materials, and making items that are the right size and shape. These perks are why they’re a key tool for making plastic items well and without spending too much.

Plastic extrusion is a key manufacturing process for making things out of plastic. It is used in many industries. From items we use every day to parts for big machines, plastic extruders are very important. They help make a lot of things we see and use.

Sheet extrusion makes flat plastic sheets. It uses materials like PC, PP, PET, PVC, and PS. These sheets are important in signs, packaging, and construction. This process makes sheets that are the same thickness. They are smooth, making them perfect for use or further work.

Pipes and tubes are crucial in many fields. From plumbing to protecting cables, they have various uses. Extrusion makes them with materials like PVC and HDPE. This ensures they are the right size and strength for their job.

Blown-film extrusion makes thin plastic films. It’s used for bags, like grocery bags, and packaging. Molten plastic is pushed through a die and blown like a bubble. Then, it’s flattened and rolled up. This creates clear, strong film that keeps things fresh.

Insulating wires is another important job for plastic extruders. Plastic is wrapped around wires for safety and protection. Materials like PVC and XLPE are used. They keep wires safe to use in many electrical items.

Compounding extrusion mixes different materials to make special plastics. This way, companies can create plastics for unique needs. They add fillers and color to get the right sort of plastic. This process is used in cars, planes, medicine, and more.

| Application | Common Materials | Key Characteristics |

|---|---|---|

| Sheet Extrusion | PC, PP, PET, PVC, PS | Uniform thickness, smooth surfaces |

| Pipe and Tube Extrusion | PVC, HDPE, PEX, PP-R, ABS | Consistent diameters, wall thicknesses, lengths |

| Blown-Film Extrusion | LDPE, HDPE, LLDPE | Thin, flexible films with clarity and strength |

| Wire Insulation Extrusion | PVC, PE, XLPE | Thermal stability, electrical insulation |

| Compounding Extrusion | Various polymers with additives | Customized properties for specific applications |

Plastic extruders are crucial in making many different products. They let us create exactly what we need by mixing materials. This is very important for many industries, bringing new ideas and better ways to make things.

Plastic extrusion machines offer many benefits, making them a top choice for many industries. They’re efficient and fast, allowing for more products in less time. This speed boosts profits by cutting production costs.

Plastic extruders can shape materials into detailed molds, which is hard to do otherwise. This means unique and complex designs are easily achieved. Because of this, products become more innovative and attractive in the market.

Extrusion lets manufacturers mix materials to create items with special properties. By mixing in additives, they can make items more durable, flame-resistant, and more. This method suits the needs of certain industries by creating specialized products.

| Advantage | Description |

|---|---|

| Cost-effectiveness | Plastic extruding machines are considerably more affordable than other plastic processing machines, making them a cost-effective solution for manufacturers. |

| Minimal waste | Extrusion results in minimal waste, as plastics can be reused and melted into different forms, contributing to sustainability efforts and reducing raw material costs. |

| Plastic recycling | The thermoplastic processing benefits of extrusion allow for the recycling of plastic waste, further enhancing the environmental friendliness of the process. |

Plastic extrusion machines have revolutionized the manufacturing industry by providing a versatile, efficient, and cost-effective solution for producing a wide range of products.

In short, plastic extruder machines have several key benefits, including:

By taking advantage of these benefits, manufacturers can improve their production. They can make products that are both innovative and environmentally friendly.

Plastic extrusion machines are great, but they have limits to keep in mind. Despite being versatile and cost-effective, they face certain challenges. These issues may affect your production and the final products you make.

Extrusion machines can only create a single cross-section type at a time. This limits the diversity in shapes and products that can be made. You might need extra machinery or more production steps to get different cross-section shapes. This could make production more expensive and time-consuming.

After extrusion, products tend to hold heat. This leads to them expanding in size unpredictably. To prevent changes in size and shape, products need extra cooling or finishing steps. Manufacturers must deal with this to ensure consistent quality of their products.

Plastic extrusion has limits on the products it can make. Items with complex shapes or designs can be hard to produce this way. Getting these products might also mean buying more machinery. For example, making UHMW and PTFE may need special extruders, adding to costs and the complexity of production.

| Disadvantage | Impact | Potential Solutions |

|---|---|---|

| Cross-section variation limitations | Restricted product range and shape diversity within a single production run | Additional machinery or separate production runs |

| Post-extrusion heat retention and expansion | Inconsistencies in final product dimensions and quality | Cooling measures and post-processing steps |

| Restricted product range and additional machinery requirements | Challenges in producing complex geometries, variable thicknesses, and intricate designs | Investing in specialized machinery or considering alternative manufacturing processes |

Knowing the limits of plastic extrusion helps in making smart production choices. It’s important to balance the advantages against limitations. This ensures the best results and cost-effectiveness in manufacturing.

Extrusion machines started in the 18th century with Joseph Bramah’s manual piston extruder. He invented it in the 1790s to make seamless lead pipes. This machine is considered the first extruder and led to modern extrusion technology.

John Smeaton improved extrusion in 1818 by patenting a twin-screw machine. This machine had two screws that could turn and force materials through. It was the start of the popular twin-screw extrusion technique.

In 1845, Richard Brooman and Henry Bewley changed the game. They made a machine that could coat copper wires with Gutta Percha. This helped the Submarine Telegraph Co. create insulated wires for cables under the sea. Their invention was a big step forward in wire coating.

| Year | Inventor | Invention |

|---|---|---|

| 1790s | Joseph Bramah | Manual Piston Extruder |

| 1818 | John Smeaton | Twin-Screw Extrusion Machine |

| 1845 | Richard Brooman & Henry Bewley | Wire Coating Extrusion Machine |

The growth of extrusion continued in the 1900s with a focus on thermoplastic materials. In 1935, the first plastic was extruded in Germany by Paul Troester and Ashley Gershoff. In Italy, Roberto Colombo created the first twin-screw machines. These steps advanced what extrusion machines could make.

Today, plastic extruders are key in making things from recycled plastics. The extrusion process uses very high pressure, up to 5,000 psi. The shape of the screws changes with the type of plastic. Most screws have three parts: feed, melt, and measure.

“The extrusion process has come a long way since its inception in the 18th century, and it continues to evolve and shape the manufacturing landscape.”

Screw lengths in extruders are often measured with an L:D ratio. A 25:1 ratio is usual for standard work. Blown film extrusion makes items like plastic bags. It mainly uses three kinds of dies: annular, spider, and spiral.

From Bramah’s early piston model to today’s complex machines, extrusion has come far. It’s used for many things, including wire coating and making plastic films. The story of extrusion shows how creative and inventive people have been in this area.

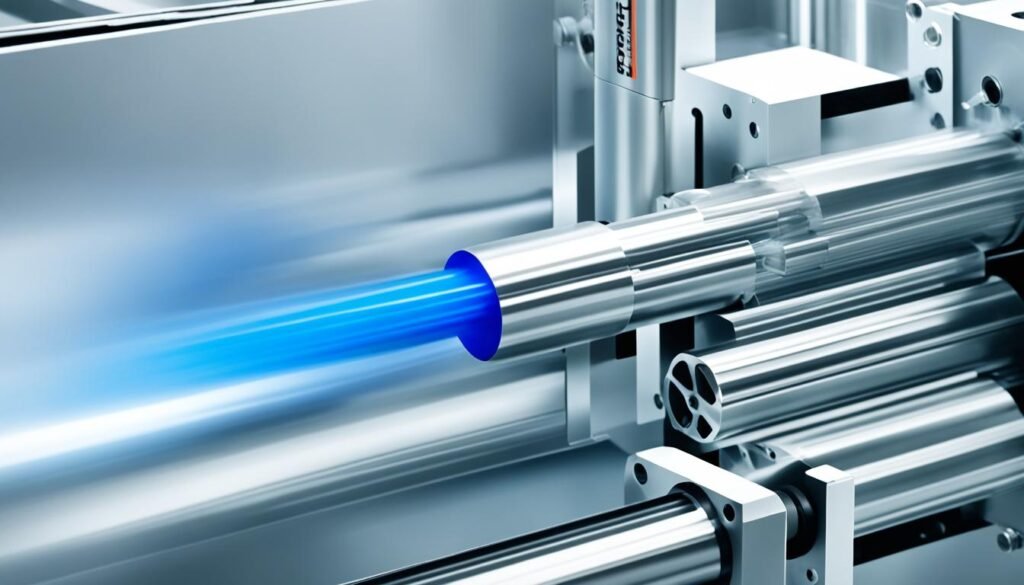

Modern plastic extrusion has changed the way things are made, from pipes to straws. It works by melting plastic beads and shaping them through a die. This makes products stronger and more consistent through aligning the plastic molecules.

An extruder machine is easy to use. It includes a hopper, barrel, screw drive, and motor. These parts work together to melt plastic beads fast. This boosts the speed of making plastic products.

Common materials used in plastic extrusion are:

The extrusion die is like a mold. It shapes the hot plastic into the correct form. The die’s design is crucial for making products the right size and quality.

| Extrusion Process | Description |

|---|---|

| Tubing Extrusion | Makes tubes and pipes. The products are cooled in water. |

| Blow Film Extrusion | Makes plastic films by expanding a tube. This cools the film. |

| Sheet Film Extrusion | Makes thick plastic sheets or films, cooled by rolls. |

| Over Jacket Extrusion | Covers wires. There are tools for sticking or not sticking the cover. |

Modern plastic extrusion makes production faster and cheaper. It’s key in packaging, building, cars, and medical tools. It sparks new ideas and growth in the plastic industry.

The U.S. has many top plastic extrusion companies. They all meet the varied needs of different fields through custom solutions and new tech.

Xometry is known for its wide range of plastic and metal extrusion services. It’s in Derwood, MD. Xometry works closely with top suppliers to provide the best molds and extrusions.

Preferred Plastics in Plainwell, MI, has over 40 years in the extrusion business. They focus on using special materials and compounds to make unique parts. This meets their clients’ exact needs.

In Middlesex, NJ, you’ll find Petro Extrusion Technologies. They are known for a large stock of products and custom-making options. The company also offers post-extrusion services for a complete customer experience.

Since 1973, Polytec Plastics in Saint Charles, IL, has been a key player in custom plastic products. They stock many types of plastic parts and can make custom designs. This ensures quality extrusions for their customers.

Ace is in Milwaukee, WI. They’re experts in making plastic tubing, profiles, and coated cables. They offer solutions tailored to what industrial companies need, worldwide.

| Company | Years of Experience | Location | Specialties |

|---|---|---|---|

| Pexco | Over 50 years | Northborough, MA | Custom plastics, engineering, and production specialists |

| Lakeland Plastics | Founded in 1962 | Lakeland, FL | Custom plastic profile extrusions for various sectors |

| Polyvisions | Started operations in 1986 | Tulsa, OK | Sustainable plastic solutions, thermoplastic resins, and additives |

| GHS Industries | Over 100 combined years | Northern Ohio | Custom plastic extrusions, tubing, profiles, and custom colors matching |

These leading companies show a strong focus on quality and innovation. They help businesses with cutting-edge tech and tailored advice in plastic manufacturing.

The plastic extrusion industry is working hard to be more eco-friendly. In doing so, companies are cutting down on waste and using energy better. They’re also searching for new types of materials that are better for the planet. One important approach to meet these goals is through recycling extruders. These machines can turn leftover plastic into something useful again, keeping it out of landfills.

Plastic Extrusion Technologies (P.E.T.) often has extra molten plastic it doesn’t need. Before, this could have added to the trash we throw away. But now, the company is making a difference by finding ways to recycle this plastic. It uses special processes to make this plastic clean and ready to use again. This way, they lower the use of new plastic and decrease the waste that ends up in landfills.

Many modern extrusion machines are built to recycle. They can smoothly mix old plastic with new, saving on waste and the energy it takes to make things from scratch. Making products last longer and easy to recycle at the end adds to this good work for the planet.

Groups that work together, like industry teams and green charities, are helping spread good ways to use recycled plastic. They encourage using both recycled plastic and new types of earth-friendly plastic. For instance, Entek has noticed more people trying out these good-for-the-earth plastics and selling more machines for recycling and making biodegradable plastic.

Bausano makes top extrusion machines and aims to save energy and reuse old plastic. They’ve come up with new tech, like special heating systems and machines just for recycling plastic. These steps support the industry’s efforts to be greener.

Turning old plastic into new stuff can be challenging because the plastic varies in quality and has moisture. Bausano knows these challenges well. They make machines that can deal with these issues, making sure recycled plastic is used in the best way possible.

| Sustainable Extrusion Solution | Benefits |

|---|---|

| Integrated regrind systems | Seamless flow of recycled material, reduced waste and energy consumption |

| Induction heating systems for barrels | Improved energy efficiency and reduced environmental impact |

| Recycling extruders for PVC and polyolefin polymers | Effective processing of recycled materials, contributing to sustainability efforts |

| Customization for bioplastics and recycled plastics | Optimal processing conditions, addressing specific needs like contamination control and moisture removal |

Bausano is dedicated to making extrusion more eco-friendly. By working with other companies, they aim to make a product that’s good for the planet while still being high quality.

Bausano is a top expert in making plastic extrusion machines. They oversee every step from start to finish. This in-house approach lets Bausano create extruders that fit customer needs perfectly, all while meeting high standards.

Operating everything internally helps Bausano customize their lines quickly. They meet specific customer wishes without delays. This combination of quality and customization makes Bausano a trusted name in the plastic extrusion world.

“Our in-house manufacturing capabilities allow us to maintain strict quality control and offer highly customizable extrusion lines to our valued customers.” – Bausano spokesperson

Bausano isn’t just focused on the first sale. They aim for long-term partnerships with their clients. They work to continually better the extrusion processes, keeping them efficient and fitting changing market needs.

| Bausano Extruder Series | Key Features | Applications |

|---|---|---|

| E-GO Single Screw Extruders | High dimensional stability, rigidity, and mechanical performance under extreme stress and temperatures | Cable ducts, edging profiles, furniture, and interior design profiles |

| Twin-Screw Extruders | Versatile and efficient processing for various materials and applications | Pipes, granules, WPC, profiles, and medical industry materials |

| Plastic Recycling Extruders | Sustainable solutions for recovering and reprocessing plastic waste | PVC, polyolefins, and other recyclable plastics |

Bausano offers a broad selection, including single and twin-screw extruders. They serve many fields, such as:

With advanced tech, customized options, and a focus on lasting partnerships, Bausano builds on its reputation. They stand as a leader in quality and value in plastic extrusion.

Plastic extruders are incredibly useful, providing a vast array of plastic solutions. They’re available in different types, like single-screw or ram extruders. This lets manufacturers pick what suits their needs best.

Customizable extruders meet various industry specifics, ensuring high precision and quality. They save money and produce excellent results.

Plastic extrusion is now focusing more on the environment. New sustainable extrusion technology aims to use recycled materials. By working with leaders in extrusion like Bausano, companies can get efficient, reliable machines that choose sustainability.

Thanks to these innovations, quality assured extrusion is now reliable. These machines improve how products are made, impacting our daily lives. Plastic extruders are key to future industry innovation, ensuring they meet market needs well.