Email:

info@miocuisine.com

Plastic extrusion is one of the many processes used in the manufacturing of plastic products. In general, the process involves the product being physically shaped by the die. The plastic products begin as raw resin which is gravity fed into a barrel that is contained in the center of the extruder. The resin is put under a lot of pressure and heat, and in the process, it melts. When the resin is in a molten state, it is then forced through a die which is a specially shaped hole that is cut through a blank. This die hardens the finished product, and it is then pulled down the line and cooled by air or water. Today, there are many products that can be made from the plastic extrusion process. Profile extrusion is the process of extruding a very long piece that has a continuous cross section, such as a pipeline or drinking straws. Sheet/film extrusion is where the extrusion temperature is so low that the resin is not in a molten state. The product is extruded and then passed between two rollers to regulate the thickness of the product. This process is used to make products such as food wrap, rollstock for lids, and blister packs. Along with the many processes of plastic extrusion come the various resins that can be used to make the product. The selection of a resin for a custom plastic extrusion project is based upon several key variables such as product usage, appearance, mechanical properties, environment, and cost.

The word “extrusion” is derived from the Latin word “extrudere” which means “to force out”. It is a manufacturing process that involves forcing material through a shaped die. The material is pushed through the die to produce an endless array of products in a uniform cross section. The plastic extrusion process is widely used in the manufacture of items such as piping/tubing, weather stripping, fencing, window frames, deck railings, wire insulation, thermoformed and injection molded products. The process is a staple to these industries as injection molding is to the manufacture of plastic products. The technique of extrusion typically uses a large screw to transport material through a heating and mixing area then through the die. Though there are some variations in this, vented extrusion mixes the material through the screw then into a cooled area and back through the screw before being forced through the die to de-gas the material. Profile extrusion is the extrusion of material through a die to form a desired shape. Flat film and sheet dies are widely used in the production of food wrap and packaging materials. Tubing dies are used for products such as PVC pipe. Re-drawing is the process of producing a small tube or rod through an extrusion die several times to achieve a desired cross section and quality, this can be done with the addition of a mandrel to the process.

To meet the demands of the fast-growing market and the need for the development of sophisticated plastic products, the extrusion process has become more important. The process serves as the main technology to produce plastic products and has generally taken over the radical job that has been done by the traditional manufacturing processes, i.e. shaping and carving items from solid plastic materials. The existence may still be there but mentioned previously, the advantages provided by the extrusion process have shown that it is a better choice to produce the same items. A simple example would be plastic tubing that has been mostly produced by the extrusion processes, replacing the conventional method of creating tubes from blowing or injection molding processes.

Plastic extrusion is among the revolutionary processes. It has generally been referred to as the preferred process in plastics to transform them into beneficial products. It provides ample benefits such as producing continuous lengthy items of a particular cross section, reduced waste of raw materials, adaptability in color or types of material, and the simple process of recycling scrap. These benefits have also been improved by the advantages that have been brought forward by the improvement in technology and other production processes.

Blown film extrusion is yet another extremely popular method that can be used to produce a large variety of consumer products packaging materials to industrial films. In a nutshell, the process involves extruding a tube of molten polymer through a die and inflating it like a balloon. The tube is then cooled by air or water and finally collapsed and wound onto jumbo rolls. From here, it can be slit and cut to size into bags or left as tubing. This process and variations of it can be used to produce anything from a trash bag to a food package. Modern-day packaging of food and consumer products is a massive global industry which has entirely converted from paper-based products to plastics. This is due to the all-round lower cost and the fact that plastics provide a much better moisture barrier, which can greatly increase product shelf life.

In today’s world of manufacturing, the value of finished goods made from plastics cannot be underestimated. From piping systems to automobile parts, plastic products are in high demand. Extrusion is a process that can meet this vast number of applications. This is due to the process versatility of extrusion, its relative low cost, and the wide range of thermoplastic materials that can be extruded. Probably the largest number of applications is the use of plastic extrusions as a long continuous profiles or a tube or hose like. This type of product is produced by the millions and is an integral part of everyday life. Window frames, sealing strips, panels, tubing, and medical IV products are just a few of the common items made this way which can be produced from many different types of thermoplastic materials.

Barrier screw design is used in special-purpose barrels. It provides separation between the melted and solid states of the polymer, improving melting efficiency and reducing the chances of solid state conveyance from one section to another section.

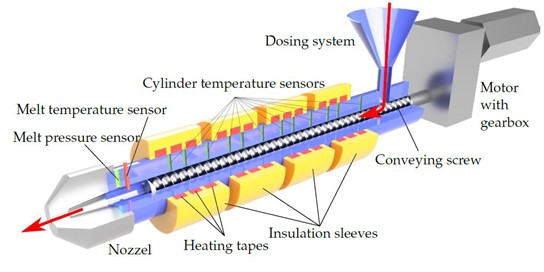

The barrel surrounds the screw and provides a means to build pressure in the material. It has several electrical heater bands to provide heat energy to the material. These bands are controlled by a microprocessor-based temperature controller. As the material continuously receives heat from the barrel, it melts and converts into a rubber-like source, causing it to start sticking to the barrel and screw. Due to the continuous movement of the screw, this sticking action can cause wear and breakage of the screw sections. Therefore, there is a provision for hard facing of the screw.

The extruder screw is the primary source of material that moves continuously from the feed to the die part. It is a precision component made through a long process. It generally has sections with different pitches and diameters. Due to these differences in proportions, it can produce shearing and compressing actions on the material. The material continuously builds up pressure while moving towards the die head. The screw’s length-to-diameter ratio governs its performance, mainly its output rate and melting capability. Modern screws are made with a large length-to-diameter ratio, allowing them to produce a high output rate and quality melting of the polymer.

Extruder components can be basically categorized into four groups: screw and screw-related parts, barrel and hopper-related parts, die and die-related parts, and auxiliary components. These all play a very crucial role in the production of small, precise, and superior quality finished products.

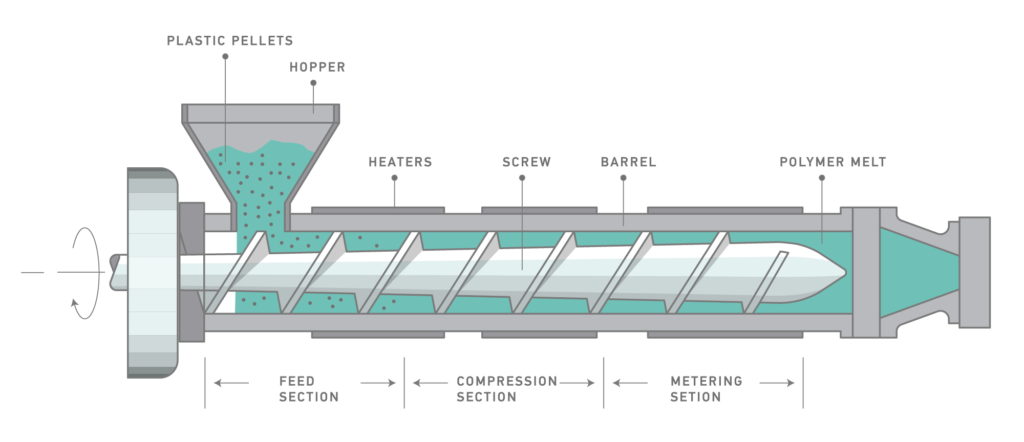

The extruder screw can be broken up into 3 distinct sections: the solids conveying section, the transition section, and the melt conveying/pressurization section. When a polymer is first loaded into the extruder, it will usually resemble the shape of the hopper, which is usually a cone. The first step of getting the material through the extruder is to feed it into the screw. In the solids conveying section, the first set of flights will compress the solid resin and force it into the first compression stage. Following that, the material will heat up and become more liquid-like, which will allow the screw to push it into the transition section. In the transition section, the material will gradually change from a solid to a liquid. If the change is too rapid, it can cause degradation and increase the chance of pressure variation. The final step is the melt conveying stage. This is where the flights become deeper and the channel tighter. This high pressure will force the material through small dies. This section includes a variety of mixing and metering devices. Some extrusion processes are shear-sensitive and will require special screws to avoid rough surfaces or lamination.

An extrusion screw is a single shaft with helical flights surrounded around it. It is used when extruding the polymer to push the material towards the die. The flights of the screw do not touch the barrel; they have a clearance of about 10 thousandths of an inch. The flights of the screw are what give it its conveying characteristics. They come in 3 different styles: solid, which is used for pellets; open, which is mostly used for sheet, very coarse materials, and mixing; and shearing section screws, which are used for mixing. Usually, a combination of all three will be used in a single screw. This is good because it allows you to get the conveying characteristics of one and the mixing of another.

Compression or Metering Section. This section starts immediately after the last of the melting section flights and extends to the start of the die. The function of this section is to melt the last traces of unmelted polymer, force dissolved gas into solution, and build up pressure to push the melt into the die. Length of this section and compression ratio of the flights must be great enough to accomplish these tasks without excessive screw RPM and resultant melt temperature increase. Usually a length from 2D to 4D and a flight depth and channel depth of about 0.08D to 0.15D is satisfactory. A compression ratio of twice that attainable from a single stage screw with the same channel depth is adequate.

Melting Section. This section extends from the end of the feed section forward to the start of the metering section. It contains flights of reducing depth with holes in the flights and the barrel itself to allow the plastic material to be conveyed by the flights while being heated by conduction from the barrel and shear from the rotating screw. Depth of section and degree of flight taper must be properly balanced with torque capability of the screw so that melting is completed by the time the material reaches the end of this section. Usually, a length equal to 3D and flights of about half the channel depth at the start tapering to solid at the end is satisfactory.

Feed section. The feed section is at the rear of the barrel. It usually contains one or two feeding flights and a smooth bore. The primary function of this section is to convey the plastic material from the hopper to the screw. A typical length for this section is from 0.5D to 1.5D with flights of the same depth.

The main function of the barrel is to transport, compact, melt, and pressurize the plastic. A properly designed barrel for a specific plastic material will meet the above requirements. It will have properly located and designed sections for feeding, melting, degassing, and pumping.

Die heads function as a tool to form and shape all types of extrudate as it makes the transition from the barrel exit to the atmosphere or into a secondary operation such as a tank or inline thermoformer. An adjustable die head allows for control in the wall thickness of the extrudate to compensate for any deviations in line speed. Usually a constant pressure type die head is utilized to reduce the possibility of melt fracture in operating at higher line speeds. Die heads for larger products such as pipe or blown film are actually formed in two halves to be assembled with the die.

Profile and sheet dies function similarly to a coat hanger as the plastic compound is fed from the extruder and allowed to flow evenly and uniformly from a slit, though various applicators can be used on these types of dies to create products such as bottles, jugs, or automotive panels. The flow from these types of dies can range from a simple flat sheet to highly intricate and multi-layered products.

Extrusion dies and die heads are made from tool steel or other high quality steels while the mandrel is usually hard chrome plated for wear and corrosion resistance. Dies are designed so as to create a shape as the plastic compound is forced through from the pressure. Dies can be of a single hole configuration to create products such as plastic coated electrical wiring or simple straws or they can be of multiple hole configurations to create products such as hoses, pipes, and some threaded parts. Multiple hole dies can even have the holes arranged in a circle or other such configuration to form a precursor product which is then further shaped or processed in a secondary operation. Single hole dies generally are used in conjunction with a pin or mandrel for shape formation and these pin and dies can often be used in place of expensive and high tool wearing injection molding dies to create the same shaped extrudate.

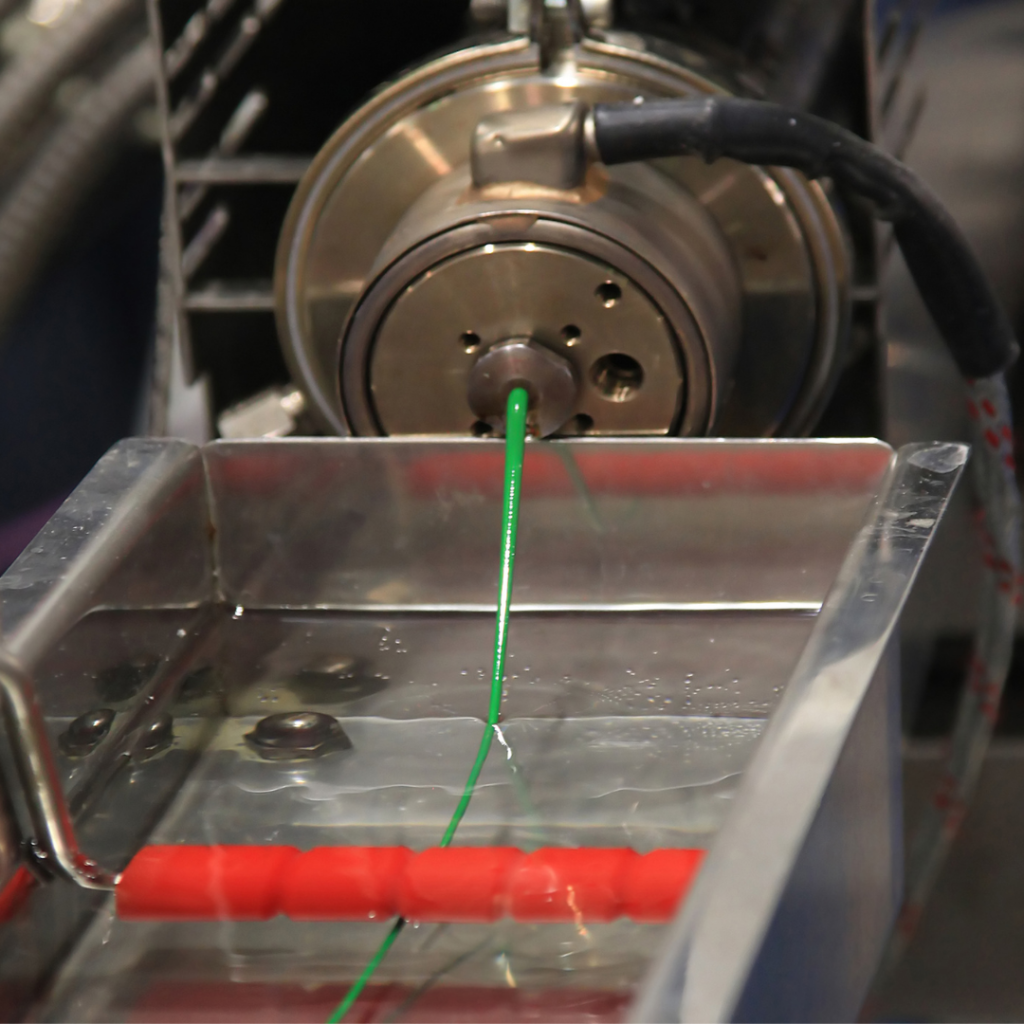

There are two factors of heat exchanges, air exchange and water exchange, that are used to cool the plastic from the heater bands to a temperature that is approachable. The cooling methods are used to regulate the temperature inside the system and make sure no plastic is melted too early or cooled too soon. Air exchange is made up of a suitable number of fans and vents. The air temperature should be controlled and a percentage of the room temperature to make sure that wayward fluctuations don’t occur from affecting the temperature desired from the plastic. Water exchange occurs in one heat exchanger which is coupled with a water pump and a temperature control valve. The heat exchanger cools water to a necessary temperature which is then pumped through and released in an area of the cooling system. 60°C water will be used to cool plastic that is to be molded for dimensional quality, while 30°C water will work for general purpose. The cooling is done in an enclosed manner to control water losses from evaporation. Evolution is another thing that must be controlled and will be in the form of organisms growing in warm water or corrosion of the metals in the cooling system. Special precautions are made to make sure the cooling system does not greatly affect the work environment with excess humidity or the introduction of contaminants.

Plastic materials are generally supplied in the form of pellets. Before the extrusion process can begin, the material has to be prepared. The first step in the preparation process is to load a hopper with the appropriate amount of plastic. The plastic is then fed from the hopper into a heated barrel through a rotating screw. Since the barrel is heated, the friction of the rotating screw will cause the pellets to gradually melt as they are pushed through the barrel. The barrel is divided into three zones. The rear zone is primarily used to build up heat. The middle zone is where the melting of the plastic material occurs. The front zone is used to regain pressure that may have been lost during the melting process. As a general rule, the temperature of the rear zone is a bit less than the middle zone and the front zone has a slightly higher temperature than the middle zone. This is to create a melting ‘transition’ that will help to reduce the chances of solid-state degradation. After the pellets have been successfully transformed into a melt, other materials such as colorants and additives can be mixed with the molten plastic in the latter stages of the material preparation process.

This is the primary stage of the plastic extrusion process. It is a very important stage that decides the quality of the finished product. If the material is not prepared properly, it will affect the entire process and result in a low-quality product. The basic raw materials for plastic extrusion are resin, colorant, additives, and many other forms of raw materials. The resin is the main component that will transfer to the finished product. The resin usually comes in the form of small pellets, with each pellet weighing around 0.5 grams. Different forms of resin are easy to handle, but they will affect the final product itself. The other materials, such as colorant and additives, come in different forms and have different weights compared to the resin. To mix all these components, the company usually uses a blending machine. In general, the material is fed into a feeder through a vacuum hose and transported to a hopper that is tied on top of the extruder machine. The material at this stage must be dry and clean for easier processing, as moisture in the material can affect the extrusion result. This is because the material is subjected to heat and pressure, and high moisture content may evaporate in the extruder, leading to an incomplete product. If the resin is a blend of color and additive, it is best to dry it into a homogeneous mixture. Drying or preheating the material may require special treating equipment.

Thermal homogeneity is essential in the melting and mixing step proper. Here, the polymer is conveyed into an extruder. The polymer is gradually conveyed and compressed to build up enough pressure to melt the polymer. Starve feeding should be minimized to prevent surging, fluctuations in output, and non-homogeneous melt. The mechanics and physics of melting and compressing the polymer are quite complicated and many models have been constructed to predict pressure and temperature changes. One of the simplest models describes the compression and melting of a solid plug being conveyed into the extruder. As the plug is pushed into the heated barrel, it reaches a depth where the pressure is enough to overcome the yield stress of the polymer. Here, the polymer begins to behave as a viscoelastic fluid. At the same time, the shearing force and resultant viscosity at the barrel wall cause the formation of a solid to liquid interface, and the plug is fully melted when it enters the metering section. This model is highly idealized, and is greatly affected by the geometry of the screw and the presence of additives or fillers.

After the drying process, the polymer particles are heated with frictional heat. This can be achieved through a variety of means. The most common method is by screw extrusion directly into the internal mixer. Others include heated, double-arm sigma blade batch mixing, and continuous roll mills. In each of these mixers, the polymer is heated mechanically using rotors or heated rollers. The extent of heating is highly dependent on the residence time of the polymer in the mixer. Generally, the polymer should be heated to slightly below its degradation temperature to minimize discoloration and degradation. Internal mixers provide the most uniform heating with the shortest residence times. Uniform heating is extremely important as it dictates the thermal homogeneity of the polymer melt.

The extrusion and shaping process transforms the material from its normal solid state into a viscous melt. The material is conveyed through an extruder, a screw drive with a constantly decreasing pitch. The depth of the screw flights becomes shallower the nearer they are to the die. This reduces the pressure and increases the temperature of the material. The design of the screw is crucial in the productivity of the extrusion process because it must provide a homogeneous melt and also develop enough pressure to drive the material through the die. The extrusion rate cannot be constant because the material will swell if the pressure is not allowed to diminish before exiting the die. A swell is the increase in cross-sectional area of the extrudate. It occurs because the pressure on the material is released when it exits the die, allowing the material to expand to its equilibrium state. A properly designed die is essential in order to produce a good quality extrudate. Dies are designed to produce a variety of different shapes and cross sections. They can be simple or complex in design and may incorporate mandrels or other devices to produce tubing or pipe. An adjustable product is produced by a die that changes its shape, for example producing a foam sheet with varying thickness. After emerging from the die, the extrudate enters a calibration or sizing device, which cools the extrudate to a temperature at which it can hold its shape. This is important in the extrusion of crystalline materials that have a semi-crystalline state. The last stage of the extrusion and shaping process is to cut the extrudate to the desired length. This is simple in continuous production of a single product where a flying knife at the die cuts the extrudate to lengths or pellets. In the production of a sheathed cable, a complex cutter may be needed to cut the cable and strip the insulation from the conductor in one operation.

The cooling and solidification stage is a crucial step in the extrusion process. It has a direct impact on the quality of the end product. The product in its newly formed state is soft and pliable and must be allowed to return to a more rigid state. To do this, the excess heat must be removed from the product to leave it in a crystalline state. The rate of cooling, as well as the conditions in which the product is cooled, both affect the final product. The greater the rate of cooling, the less time the polymer molecules have to form into the crystalline structure, and instead, they arrange themselves into random formations. These random formations create weak spots in the product and can cause warping or changes in shape. Rapidly cooled thin-wall products are especially susceptible to warping, while thicker products may crack because of high internal stresses. A slow, uniform cooling process is required for all products. This can be achieved with air cooling in ambient temperature air; however, this method can be quite slow. Immersion in cold water is faster, but this can affect the surface of the products, especially in the case of PVC products. Spray cooling with water is the most versatile method. It allows for the control of the rate of cooling and is suitable for products of all shapes and sizes. The changes in conditions can be made simply by changing the distance and angle of the spray. An emerging technology for cooling and solidification is using liquid nitrogen. This allows for extremely rapid cooling and is especially useful for certain types of pipe products.

Cutting is the process of molding the extruded parts while they are still soft. This is applicable for hose, profile, film, sheet, pellet, and pipe products. There are several things that can occur before the cutting process. Primarily, there is puller consistency, just like in calibration, the puller must pull the extruded part at a consistent pace. If this is a servo-driven puller, the acceleration and deceleration rates may need to be adjusted to attain the desired consistency. If the puller is not consistent, it can cause the product to bunch or bulge. If the extruded part is not round, this might be the result of an inconsistent puller. If the part is to be cut while still soft, the consistency of the puller is much more critical. Many methods take place on pipe and tube extrusion where the pipe is coiled and will not be cut until after it has been wound. Commonly, for profiles and hose products, the extrudate will travel down a conveyor and enter a water trough, then travel through a set of guide blocks to divert the extrudate into a coiling mechanism. If the extruded part is to be cut at a specific length, it will run through a cutter on the conveyor. For universal cutting of parts still on-line, a hot knife may be used with a programmed stroke to cut the part off the line. This can later be done using a similar method to pellet cutting, still using a hot knife to cut where it falls into a slanted chute and enters water to cool and harden. Usually, it will pass through a water chamber after it has been cut or scored to ensure shape retention before final cooling.

Each of the above considerations involves the collection of data followed by analysis and possible control action. Quality control in extrusion is no different from the process in other industries of converting raw materials into finished products. We all want to produce a product which meets certain specifications, at minimum cost and to do this with minimum scrap. The effective control of an extrusion process has much to do with the behavior of the extrudate as it leaves the die. Problems which arise later in the production line or even after a product has been supplied to a customer can often be traced to process conditions in the later stages of the extrusion. At this point in time it may be too late to implement changes to avoid repetition of the problem next time that particular product is scheduled, therefore it is important to control all aspects of the process. The product must then be monitored at regular intervals and tests conducted which provide enough data to ensure that the process is stable and is in a state of statistical control. Random samples can be taken of the product and a control chart plotted for a number of variables such as dimension and weight. These control charts monitor the upper and lower control limits – the point which if exceeded indicates that the process is out of control. On many occasions the operator will be able to relate changes in the process to specific defects in the product. In such cases the cause of the problem could be an error in data acquired by conducting tests or it could even be due to absence of a particular test. Therefore the suitability of a test in detecting defects as well as providing data which is useful for process diagnosis is an important factor in determining the quality of an extruded product.

Temperature measurement is achieved with thermocouples which are located at given sections along the barrel. The barrel is divided into 3-6 temperature control zones extending from the rear barrel to the die. Each zone is to be set at a temperature and is equipped with one or more thermocouple sensors and a heating/cooling unit. Discrepancies between the set and actual temperatures are indicated on a control panel and give indications on whether to increase or decrease heating/cooling output to the section. A more recent development in temperature control monitoring system is through the use of infrared temperature detection sensors. These sensors provide a non-contact method of obtaining the surface temperature of the extruder barrel and are able to detect temperature anomalies at early stages which cannot be detected through standard thermocouple. Temperature measurement can be correlated with pressure measurement as shown by Eldridge and Troughton.

After suitable quality product through plastic extrusion is defined, exacting on the process to take possible corrective action when and if needed to maintain the product quality before unacceptable variation in product quality occurs. One of, if not the most effective way to control a plastic extrusion process is through careful monitoring of the barrel temperature and the pressure at various locations within the barrel and die. Monitoring the temperature of the barrel and die is critical in controlling the plastic viscosity during the extrusion process. Each different resin type has a specific processing temperature yield the optimum viscosity for extrusion. When the resin is too cold it has a higher viscosity and results in greater frictional pressure inside the extruder. High viscosity could also lead to the possibility of non-uniform flow. Conversely, when the resin is too hot it will result in thermal degradation of the polymer with the possibility of resulting in unwanted gels or degradation by-products in the final product. Small temperature fluctuations or changes can have significant effects on the process which make it necessary for some method to measure temperature changes at various locations within the extruder. The temperature must be accurately controlled on most resins to within 5°C.

The control of dimensional accuracy is an essential issue in plastic extrusion. Dimensional inaccuracy is the commonest reason for rejecting extrusion products. ATeX measures have been developed for extrusion. Capitol Scientific (1995) describes a laser-based technique. An alternative to such off-line measurement is to use in-line measurement of diameter and wall thickness. Jim Finnegan (1995) describes an ultrasonic technique. A more indirect assessment of dimensional accuracy is to measure the changes in weight per unit length. These can be monitored continuously in real-time and used to make rapid corrections to the extrusion process. An example of a weight monitor is a device marketed by T.G. Hegler. Continuous online monitoring of weight variation can also be used to judge the stability and repeatability of the extrusion process, by comparing batch-to-batch and within-batch weight variation. Dynamic mechanical analysis (DMA) has been used to characterise anisotropic changes in dimensional stability of plastics extrudates.

Tensile tests, which involve the application of a force to a sample by grips at either end and measure the force required to pull the sample apart, or deformation caused by loading. The stress and strain are calculated by dividing the force and extension by the cross-sectional area of the sample and the gauge length respectively. If the test continues until the break, tensile strength will be determined. Tensile tests can provide a measure of stiffness in terms of secant or tangent modulus and can be related to both service conditions and more complex forms of analysis.

Simple tests used widely today on extruded plastics for stiffness and strength include flexural and tensile tests. Flexural tests, used to determine properties of materials in bending, involve loading a standard sample type until failure. The strength is calculated as the force applied divided by the cross-sectional area of the sample at the fracture. Often flexural modulus, a measure of stiffness, is found by determining the slope of the line in the elastic region of the stress-strain plot. It is usually expressed as force per unit area. These tests are useful because they are simple to do, can be related to service loading conditions, and test equipment has been developed specifically for testing plastic materials.

The final aspect of quality commercially oriented involves testing of the final product. In the case of plastic extrusion, this would mean testing the mechanical properties of the end product. In order for tests to be meaningful, we need to measure properties that are important and can be related to end-use performance or behavior in service. Broadly speaking, these properties can be sized into categories such as measures of stiffness, strength, toughness, and service performance.

Though the process does allow for easily pinpointing and identifying defects, it is not without need for specific and dedicated methods for inspection and analysis of defects. Gels and other defects in the product can often gum up or even damage tools used for further examination or cutting the product. This makes identification of the defect difficult and can actually create additional defects. Other problems are apparent only in poor performance in the end-use application of the product. Because the defect was not entirely visible it may have gone unidentified as to its cause. This highlights the importance of immediate recording and documentation upon discovery of defects in an effort to understand and prevent the problem.

Defects in extrusion products can occur at any step in the process from the plasticizing of the resin to the final take up of the product. Typical defects are usually in the form of gels, discoloration, voids, poor surface quality, dimensional variability and the windup product not meeting specified thickness. The location of the defect on the final product and an idea of when the defect originated are important in determining the cause of the defect. A review of the effect on process conditions sensors, screw and die design can often identify the source of the problem. Detecting when a problem first began to occur is one of the advantages of extrusion, tools can be used to cut the product and look at cross sections to determine when the problem started.

When a defect in a plastic product is discovered, examining the manufacturing process and the product can provide valuable information that may prevent similar failures. This is particularly true with plastic extrusions because the extrusion process offers several opportunities for examining the product for defects. Extrusion offers a continuous process wherein the product can be monitored and adjustments made quickly. This provides significant savings when compared with other plastic processing methods wherein the product must be completely formed before a problem can be detected and rectified. With injection molding for example, if a problem is detected when the mold is opened the product is essentially scrap and the mold must be re-run after adjustments are made. With extrusion, the product can be cut at the point where the defect began and the process can continue immediately following adjustments.