Email:

info@miocuisine.com

Overview of Plastic Extrusion Machines

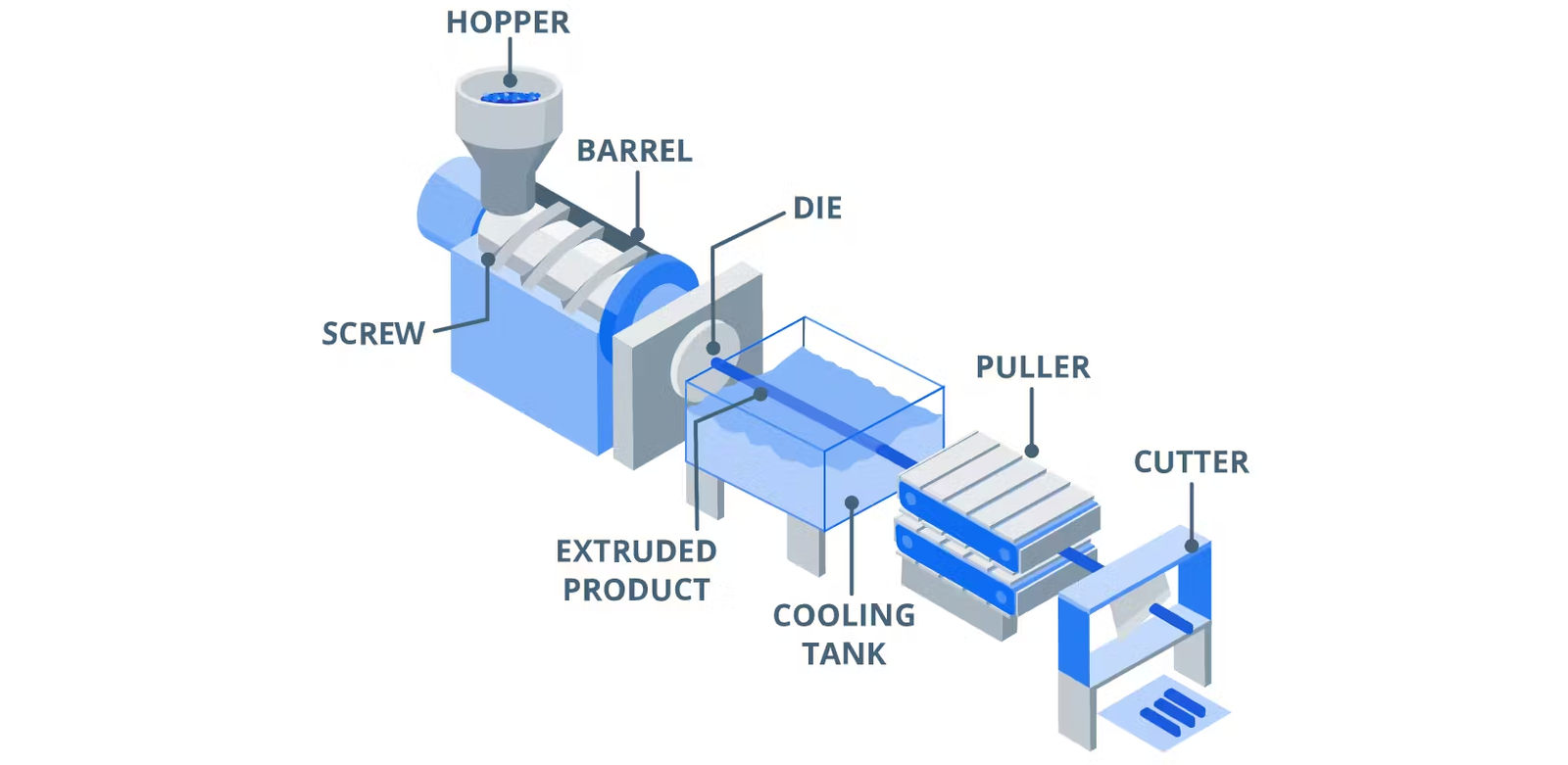

Plastic extrusion is a continuous and automated manufacturing process during which a raw plastic material is melted and formed into a continuous profile. Extrusion is employed to create things like pipe/tubing, weather stripping, fencing, deck railings, window frames, plastic films and sheeting, wire insulation, and plenty of different types of consumer and industrial products. Extrusion might be a cold or hot process. During a hot extrusion, the material is heated up to higher than its glass transition temperature and is able to flow. Most extrusions are cold, taking the feedstock through room temperature die. Since 1970, advances in control of the method have enabled significant increases in productivity and product quality. The material properties of plastics are determined by the microstructure of the polymer. Besides product quality, there are many controlling factors throughout the extrusion method that limits productivity. High productivity will negatively impact both the quality and properties of the extruded product. The extrusion method is basically the same as a person who forces toothpaste out of a tube to wash their hands. The engineered system that controls this method is outlined as a screw installed in a cylinder. The screw in a plastic extruder consists of a rotating screw encased in a cylinder. The plastic granules are freely fed into the top of the extruder and are contained and compacted by the rotating screw as it advances toward the die. During this method, the plastics are heated by mechanical energy from the screw and heater temperatures so that the compaction method becomes complete. An accomplished extrusion method can be outlined as this: molten at the end and solid from the process.

The next section of this essay will discuss many types of extruders and method configurations presently utilized in the plastics industry and then describe the limits to high productivity.

Current State of Plastic Extrusion Machines

Major developments in plastic extrusion technology in the last 10-20 years have greatly increased the ability of plastic extrusion machine to produce a large number of compounds and higher quality products. This has been achieved largely through improvements in venting and the screws and barrels used in the extruders. These two changes have been the most significant in terms of enhancing the ability of plastic extrusion machines to produce high quality products. Vented extruders have allowed a much greater level of control over the temperature of the plastic being extruded. This is due to the fact that with vented extruders undesired gases can escape from the polymer as it is being melted. This is very important as different polymers will break down under a different amount of heat and the ability to remove and control the temperature of a given polymer can greatly affect the quality of the final product. Studies have shown that temperature irregularity throughout the product is a common problem with non-vented extruders; venting is able to eliminate this problem. Temperature control can also be achieved through the use of a wider variety of screws and barrels. High torque screws have been developed that increase output rates and temperature control due to a better conveying of the polymer. In order to increase the time the polymer is in the screw and therefore increase the homogenization of the polymer and temperature control, screws with a higher L/D ratio (length to diameter) can be used.

A method has recently been developed to predict the temperature of polymer at the die in an extrusion process. This method actually came from the understanding that different methods of simulation in finite element analysis gave different results. It was discovered that for each simulation round the polymer would have to have its own unique set of material properties in order to be simulated predictably. This has led to a system (a ‘state’ variable constitutive model) where the change in material properties due to temperature can be predicted. This can be used to make changes to the extrusion process in order to achieve optimum temperature and material property conditions required. Otherwise, computer simulations of the extrusion process have also been used to increase the understanding of what is happening in the extrusion process. Such simulations have been able to increase the understanding of the effects that the die swell phenomenon and other complex rheological effects have on the extrusion process.

Emerging Technologies in Plastic Extrusion

There are some new, relatively untested technologies that are just starting to make their mark on the industry. One of these is microcellular extrusion. This process involves adding supercritical CO2 to the plastic, which then bubbles out during extrusion and blowing, leaving a finely celled structure. Microcellular foam has a number of advantages over standard foam products, including a smaller cell size, thinner skin, and better material distribution. It has more applications than standard foam, including resilient bumpers, automotive components, and medical products. Though the technology is relatively young and has a number of constraints, microcellular extrusion looks to be a significant development in the near future.

Another emerging technology is the use of electric extrusion machines, which are set to significantly reduce the power consumption and costs of extrusion. Traditionally, extrusion has been carried out using hydraulic machines, but market trends suggest that the electrification of machines is quickly becoming popular. Extrusion uses up a vast amount of power, much of which is dissipated as heat by hydraulic machines. Electric machines are able to significantly reduce energy costs and provide potential for the re-use of the energy generated during the cooling phase of the process. However, in reality, it will probably be a long time until electric machines become mainstream, for they are still relatively expensive and struggle to provide the high force and pressures of hydraulic machines, although it is likely that this will change with time.

Potential Applications and Benefits

Further development in this area will benefit from a machine capable of extruding a wide range of polymers but with quick and easy changeover between materials. This would negate the requirement for multiple machines for the fabrication of trial products. The ability to produce trial products on a small scale before moving to mass manufacture is another advantage of developmental plastic extrusion technologies, and rapid prototyping for new products will become more widely used. These areas will benefit from work on machine designs optimized for specific polymers or material groups.

Recent work towards single-step, direct-from-resin methods for creation of complex shapes is being applied to the development of medical devices and drug delivery systems. A significant industry has built around polymer hypodermic needles and syringes.

Developmental plastic extrusion machines are finding an expanding array of applications across a number of different industries. The research and development at Queen’s in the area of food extrusion has resulted in a biodegradable pre-packed sandwich container from an expanded foam thermoplastic. This is non-food-contaminative, floats in boiling water, and provides excellent insulation. Extrusion of thermoplastics in food packaging applications is becoming a very useful and popular method for creation of both thin films and complex shapes and sizes. The vast range of thermoplastics available, coupled with the ability to add color and/or additives, has resulted in plastic materials that can meet a tremendous array of requirements at a cost that is competitive with traditional materials such as glass and metal. FDM type processes for biodegradable polymers are also becoming more commercially viable in an attempt to lessen the impact that polymer disposal has on the environment.

Key Findings and Recommendations

The key findings of the project have been the high energy use of the extrusion process and the associated high heating costs. The energy use survey showed that on the two weekends, over 60% of the energy consumed by the extruder was used to heat the barrel. The average was 49.9%. During the surveys, the mean energy consumption figure was 13.1 kWh. This means that on average, 6.52 kWh was used for heating, with an average cost of £1.63. This effectively means that, on average and in an ideal scenario, £35.72 is used to heat the barrel over a shift. With 11 times shift duration, this means an average of £39.32 per shift and a total of £782.83. This is an excessive amount of heating and therefore indicates that insulation of the barrel can be employed to reduce costs. The designs previously discussed in the section have been entertained and modified to give a product using the materials “Calcium Silicate and Fused Silica”. The design consists of three separately fitted sections for each barrel, which are each insulated by a casing with a 40mm air gap from the barrel. This will reduce heat loss through radiation and convection by 95%. Therefore, 228% less energy will be required to heat the barrel, with an overall total of 5.4 kWh per shift and a potential cost of £14.85. Therefore, it has been shown that insulation of the barrel using this product is effective in reducing costs, and it is recommended that a prototype be produced to back up this theory.