Email:

info@miocuisine.com

This paper consists of two sections. The first section is a point by point benefits of all electric and they use this technique to better explain the second section which is pointing out the disadvantages of all electric. These details are provided to help a potential end user decide if either type of machine is the right choice for the production process. This paper is not intended to be an engineering study on comparing the two technologies, but rather a guide for decision making for a molder. Section two is a contrast of the two types of injection machines. All electric has its benefits, but they are not always better than hydraulic machines. The following will provide examples of why these are not always an improvement over traditional machines. This will then be used to better explain the pros and cons of all electric injection molding in section one.

The all electric injection units use only the energy required to process the material, which can be up to 70% less than the energy used by a standard hydraulic system. This results in potentially huge energy savings, especially for operations with high production volume. More available production energy at the same consumed power allows faster and more accurate processes and thus a shorter cycle time, while avoiding peak power consumption and the effect of slow process speed due to low oil temperature. This can be a direct advantage with existing molds.

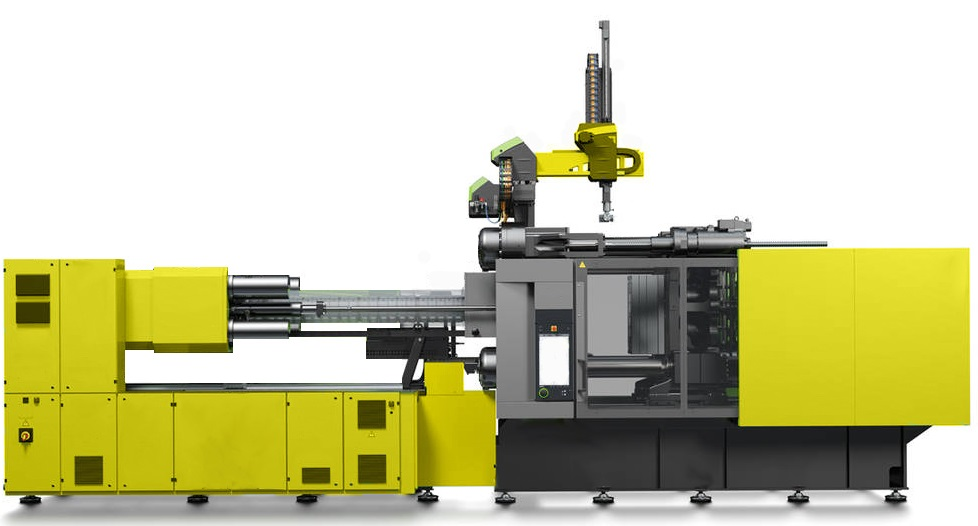

All-electric plastic injection molding machines are known for having higher precision, a more compact design, and a higher efficiency of the electric servomotor type drive system, resulting in a cleaner and quieter operation than hydraulic machines. There are a number of additional pros to running all electric injection molding machines. These include faster cycle times, better part tolerances, and lower maintenance requirements. Let’s take a look at the advantages that all electric molding machines have over hydraulic presses. This information is directly from a machine supplier and should be used as a general guideline in considering the capabilities of electric molding. As with all process technologies, the sum of the capabilities will differ with various suppliers.

Higher capital investment, severe limitations on maximum shot capacity, precluding use in packaging and similar applications, and the lack of a high production rate are the main disadvantages of all-electrics. Capital cost for all-electric machines is higher than that for hydraulic machines due to a higher level of complexity. While initial costs for all-electric machines are about 20% more than that for hydraulic machines, all-electric machines result in cost savings of about 50% in energy savings. Shot sizes for all-electrics are about 10% less than hydraulic machines due to limitations in available screw designs and electric motor capacity. Even with recent developments in electric motor technology, all-electric machines still have inadequate screw torque at higher screw speeds, necessary for processing of many engineering plastics. High torque electric motors can solve this problem, but these motors are less efficient, negating energy efficiency advantages. High production rate is not feasible for all-electrics due to limitations in motor speed and the need to recycle and regenerate motor braking energy in order to capture the full benefits of energy efficiency. Simulation exercises have shown that production of small parts in long runs, or parts which require thin wall thickness, are best suited to all-electric technology.

A variety of industries can benefit from the cleanliness and precision of all-electric plastic injection molding machines. In the automotive industry, because the parts are larger and require more force to mold, hydraulic injection molding machines are typically used. However, more and more companies are seeing the benefits of smaller, cleaner, more efficient machines in their quest to cut costs and reduce waste. The medical industry has very high standards of cleanliness and precision, which makes all-electric machines very appealing. In addition, there is a growing need for small high precision plastic parts. The consumer goods industry often produces a large number of plastic parts, frequently using a high number of plastic injection molding machines. JIT inventory systems are becoming more common within this industry, and one way to cut costs and increase productivity is to utilize all-electric plastic injection molding machines. The machine will pay for itself in the long term because of electricity savings and through less downtime due to long-term part savings.

Automotive industry is a rapidly growing industry with a high production rate of items using injection molding. Products such as bumpers, door panels, light housings, and many other items are being produced in larger quantities, and many companies are concerned with the environmental impact and the energy used to produce these parts. One company, discussing the implementation of injection molding in the automotive industry predicts that a new injection molding process will be developed focused on the environmental impact and energy reduction. Based on the usage of this molding technology and its prediction, it is clear that all-electric machines will be a large part of the future in producing plastic automotive parts from the entry level market through high end luxury vehicles. The automotive industry is a field with high competition and high product turnover making cost efficiency a key with the added pressure from today’s economical state. Injection molders in this industry will find a great benefit with the repeatability of all-electric machines and the energy savings from their efficient use of power. With the development of higher tonnage machines, automotive molders are now able to run larger tools that were previously run on hydraulic machines. As the technology of all-electric machines progresses in development larger tonnage machines will become more feasible. Although the primary concern in today’s market is a low price point for manufacturing. High initial investment for an all-electric machine can deter some automotive molders from the switch to all-electric, but with its long term savings and shift in consumer perception toward environmentally friendly products, it will undoubtedly be market standard in the years to come.

The market for plastic injection molded parts in the medical industry is substantial, and it is expected to grow to $1.9 billion by 2012. This was echoed by Jay Cude, President and Founder of Isometric Micro Molding, Inc. in his keynote presentation to the Molding 2007 conference. He stated that minimally invasive equipment and devices are fuelling much of the growth, and 20% of that equipment is still made of metal. This represents an opportunity for conversion. New materials are also driving growth in plastic parts, and the development of bioresorbable polymers will open new doors for plastic injection molding. With the growing concern about the environment, it is believed that these bioresorbable polymers will be a tipping point to switchover from metal.

Medical industry is growing exponentially due to increasing age population and awareness of health. The main consumer of plastic parts is in the area of disposable items of equipment. The industry relies heavily on automation, because the cost of manufacturing is high in developed countries. A general shift in the health care industry has been witnessed, moving of the production of medical goods out of Western countries. This is driven by cost reduction requirements. Projection is that the industry will continue to move to developing countries over time. Medical goods are a good fit with the injection moulding process. High production rates are not generally required for items such as syringes, blood sample capsules, catheters etc. and so a high number of cavitation mould tools can be put on one machine, to maximise the use of the machine in a cost effective manner.

As Mireya Gaviria explained in her 2007 article “Plastics technology, the consumer goods industries, and the environment,” the consumer goods industry is important in decision making about what type of processing machinery and raw materials to be used. The widespread consumer acceptance of products made by plastic injection molding, such as pens, toys, mugs, and containers, makes this industry a key market for injection molding machines. The article also stated that though there are hundreds of different plastic materials, familiar consumer goods are typically made from a small roster of commodity resins and in small part sizes. Since these goods are often produced in very high quantities and the consumer goods industry is very price-sensitive, the high volume capabilities of injection molding are a perfect fit. All-electrics are especially well suited to the consumer goods market because the consistently high quality and repeatability is of much higher importance in industries with low product margins and high production volumes. High quality and energy efficiency, coupled with the elimination of hydraulic maintenance and part quality inconsistencies, are the main reasons that consumer goods suppliers are increasingly demanding all-electric machines. This is beneficial for the environment and likewise for the industry because the growing number of regulations and conventions against the usage and disposal of plastic products are causing many suppliers to switch to more environmentally friendly production methods and materials.

A cost analysis for implementing an all-electric plastic injection molding machine should be considered against a hydraulic machine mainly to understand the difference in initial and running cost. Lower running costs associated with electrical machines can be explained by greater efficiency and less maintenance requirements. This is understandable because energy cost is a major factor in the total cost of ownership. However, it is less clear when considering a new machine purchase, as all-electric machines are still more expensive to purchase than hydraulic machines. Steps need to be taken to ensure an accurate comparison between the two types of machine, particularly in defining the expected lifespan of the machine and expected running time. More accurate results can be obtained by using actual electricity and hydraulic fluid costs from the factory. Future energy cost increases should also be considered, as energy prices for hydraulic machines will always become more expensive, while efficiency increases and use of more renewable fuels by energy providers may reduce the cost gap for electric machines. When comparing machine prices, it must be noted that in general the gap in cost between electric and hydraulic machines is reducing, and as the market for electrical machines grows it is likely that a price parity will be reached.

In summary, cost comparison can be complicated due to the differences in electric and hydraulic machine capabilities. If process changes can be identified it may be possible to cost save in specific areas, but also the increased capabilities of electric machines may result in increased expenditure. Simulation of these expected process changes using electric machine functionality will provide a more accurate cost comparison. The high initial cost of electric machines can be offset by the often identified long-term cost savings resulting in an overall TCO lower than hydraulic machines.

The primary motivating factor for implementing any new manufacturing equipment is the perceived tangible benefit, in this case cost reduction, achievable through said implementation. To ascertain this, the costs incurred through the lifespan of the equipment must be weighed against the cost of the equipment itself. To ensure realistic comparison, costs incurred by both electric and hydraulic equipment in like duties must be compared. This can be difficult as the capabilities of electric machines often allow functions not possible on hydraulic machines, thus providing the opportunity for process change leading to cost saving. In this situation an educated guess based on past processing methods must be employed. In contrast, simple cost comparison of like for like equipment can be very clear cut. The typically higher cost of electric machines can be a deterrent, except when long-term running costs and total cost of ownership (TCO) are considered.

The first equation can be used to compare the energy cost of the same machine over varying electricity rates and the second can be used to compare different machines. High efficiency to a manufacturer with a high electricity rate will have a significant impact on operating costs.

Electricity($) = (hp x kW) x 0.746 x hours x rate / motor efficiency Electricity($) = (hydraulic power) x (1/mechanical power) x (time) x rate / motor efficiency

Machines with hydraulic units will have varying energy costs. It is important to remember that energy cost is approximately 95% the value of electricity. It is determined by dividing the hydraulic power by the mechanical power. The hydraulic power can be found by using a gauge on the machine and the mechanical power is determined by the machine torque and velocity of the screw.

There are many different varieties of cost associated with purchasing a molding machine. Here is a short list of things to consider: – Utility Price: The energy costs on the invoice from the utility company that the consumer will pay. – Demand Charge: Many utilities place a fee per kWh on the rate because of the peak power the consumer uses. This will make time saving devices more valuable and machines with a lower kW rating cheaper to operate. – Internal Capital: This is the cost to the company of investing in new equipment or taking equipment off line. High cost equipment will have a higher capital cost. – Environmental Cost: An emissions conscious company may place a value on reducing energy consumption to lower the impact on the environment.

Analyzing the energy costs of various processes is very complex and needs to be done. There are some strict guidelines on how to account for energy costs. It is important to account for the equipment over varying time periods. The energy cost of production equipment for a given month is the amount of energy the equipment consumed during the month.

There is a difference of opinion in the data from the two companies – one suggesting higher total costs due to more maintenance workers and the other suggesting lower costs because of substitution of a single skilled electrician for several less skilled ones. Although both companies have found ways to decrease the overall costs associated with maintaining all-electric machines, the fact still remains that electric machines are more complicated and maintenance cost savings is not as evident as the energy savings. One of the companies mentioned that the increase in maintenance costs is marginal and the reasons for maintenance activities such as lubrication of the hydraulic machine and checking hydraulic oil is eliminated with the use of the all-electric machine. This statement is supported by the fact that there is no maintenance cost associated with parts replacement using an all-electric machine. Computer simulations show that the maintenance and replacement costs of electrical and electronic components are significantly lower than those for electro-hydraulic machines due to the increased life of electric devices. However, these results were inconclusive and indicate a need for further research on the subject comparing the life-cycle maintenance costs of hydraulic and all-electric machines.

It is not uncommon for a product to be held to ransom from its design when considering the price of the mold or the capital equipment available. This often results in a lower quality product or a change in the design to be more “molder friendly”. With the improved stability and repeatability from an all-electric machine, the process at the design stage can be more versatile as there is less variation in the process. This makes it an easier decision for the manufacturer to wait until a quality mold can be produced for higher accuracy and repeatability. A market research Kraft app stated that 37% of professionals in the plastics industry blame production of non-conforming parts on flaws in the molds. An all-electric machine can also help to alleviate this problem by making the mold testing. During mold testing, there are parameters setup and this is often where the process engineer will find the best settings for molding the part but it can come at a cost due to the possible damage to the mold. With the improved stability of setting, finding the correct settings can be much quicker and require fewer adjustments so it can reduce the number of tests and the opportunity of damage to the mold. This reduction in variation and calibration can create a huge cost saving for the customer and the process engineer as a more efficient process can be charged at a lower rate of production. This is desirable for the market of rapid prototyping where all-electric machines are not yet widely used, it is however growing in this market due to possible savings on select materials by overmolding to test part functionality. With time, the electric machine will become the most viable option for this application.

By the very nature of how they operate, all-electric molding machines are data rich. For example, of the molding processes currently being used, one of the cleanest is all-electric injection. This is due to the fact that there are no hydraulic valves or cylinders sprayed with hydraulic oil. Without going into too much detail about hydraulic injection molding, the old conventional type is very wasteful in the energy consumed during the process. With the hydraulics, there are various types of energy loss such as that from missing non-return valve or pressure valves. And the two big energy wasters are the motor while the hydraulic compound is not being used and the overproduction of heat from the multiple hydraulic valves and resultantly air conditioning the oil. An electric machine can be powered 40% on average lower than the hydraulics. This is a very big advantage. So the electric machine will give us a far more efficient and cooler running option in injection molding. This has a noticeable impact on the state of the mold and the molded part.

The injection molding industry has made great strides in improving efficiency. The shift from hydraulic injection molding to all-electric has led to substantial benefits, including increased precision and repeatability, lower operating costs, and reduced waste. The next phase in the progression toward improved efficiency involves using the data these machines generate to identify and eliminate inefficiencies in the molding process. This can be accomplished through the integration of the Internet of Things (IoT) and Industry 4.0 technologies.

At its core, Industry 4.0 represents the fourth major transformation in production and manufacturing – a wake-up call to businesses to challenge the status quo and align their technology and practices for a new era of automation and data exchange. Dubbed the Industrial Internet of Things (IoT), the melding of these physical and digital systems represents a significant stride in successful data management, offering potential for vast improvements in manufacturing efficiency, flexibility, and automation. It’s with these concepts in mind that the next generation of plastic injection molding machines should be conceived. Strategies here can be as simple as monitoring the utilization of machines or as advanced as enabling the machine to reprogram itself to achieve an optimal state with very little intervention from an operator. Injection molding specific applications that would profit from these advancements would be the development of simulation software with the ability to share data between systems in order to improve accuracy and the precision with which a part can be molded. This link between simulations and the physical machines would be powered by data coming from the molding process, and the machines would be able to respond to simulation predictions by automatically adjusting process parameters. The goal is not to attempt to bring Industry 4.0 technologies to the level of sophistication we see with injection molding machines of today, but to first quantify and qualify the benefits that can be gained by doing so, and then prioritizing development efforts based on the value each new feature or technology can provide to the industry. In simpler terms, the capabilities of today’s machines are vast, but connecting them to the digital age will allow businesses to operate them more cost-effectively and enable technologies that allow machines to do more on behalf of the operator.

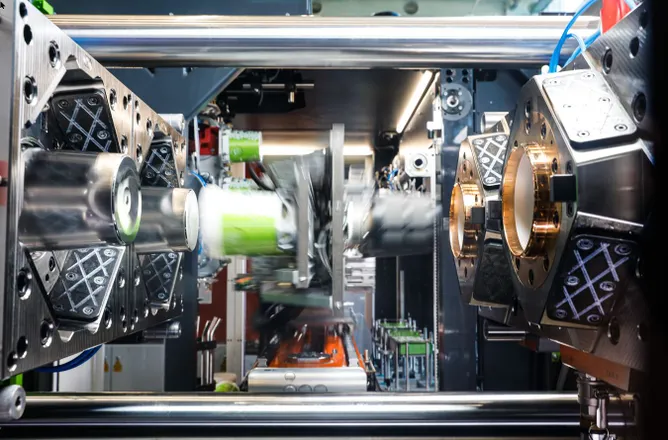

Microcellular Injection Moulding (MIM) is a much more radical process involving the creation of a foam-like structure within the plastic part. This is achieved by dissolving gas into the polymer and then allowing it to expand into the mould during injection and solidification. The technique is very versatile and can be applied to most thermoplastic materials with the creation of a solid/gas hybrid. MIM provides benefits of reduced part weight, sink mark elimination, improved dimensional stability, increased strength and rigidity, and comes at cost savings due to elimination of secondary foaming operations. This process is quite revolutionary and has the potential to redefine the ways certain plastic parts are produced.

Structural and Microcellular Injection Moulding are new processes that have been developed to meet demands for low weight and material savings in consumer products. Structural Injection Moulding is a hybrid process between injection moulding and film/sheet thermoforming, designed to overcome the limitations of hollow moulding in thickness, strength, and quality. It allows for much improved strength in ribbed or reinforced plastic parts and produces surfaces with superior aesthetics. This is achieved by heating the polymer above its glass transition temperature and then using low pressure injection and clamping on modified machines. The process allows for reduction in part weight and material with low investment cost and has potential to replace standard injection moulding in many applications.

There is now an imperative to design and manufacture products that are more energy efficient and cost effective. This needs to be achieved with increasing recognition of social responsibility and environmental considerations. The emphasis in designing and engineering products not only requires a sound understanding of materials behaviour but also demands the utilisation of more sophisticated methods and tools. In recent years, the development of these methods and tools in the Injection Moulding industry has resulted in significant improvements and exciting opportunities. These have been realised through advancing technologies in moulding processes and material sciences.